中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

Introduction to Automatic Explosion-Proof Devices in Coal Mines

Automatic explosion-proof devices play a critical role in ensuring safety within coal mines, where the presence of combustible gases and dust poses significant risks of explosions. These devices are designed to detect potential hazards, mitigate the risk of ignition, and protect workers and infrastructure in hazardous environments. Here's an overview of automatic explosion-proof devices used in coal mines:

Gas Detection Systems: These systems employ sensors to continuously monitor the concentration of combustible gases such as methane (CH4) and carbon monoxide (CO) in the mine atmosphere. If gas levels exceed predefined thresholds, alarms are triggered to warn personnel, and automatic shutdown mechanisms may be activated to prevent ignition sources from causing explosions.

Dust Monitoring and Control: Dust particles suspended in the air can also pose a significant explosion risk. Automatic dust monitoring systems measure the concentration of airborne dust particles, and integrated control mechanisms can automatically activate dust suppression measures such as water sprays or ventilation systems to reduce the risk of explosion.

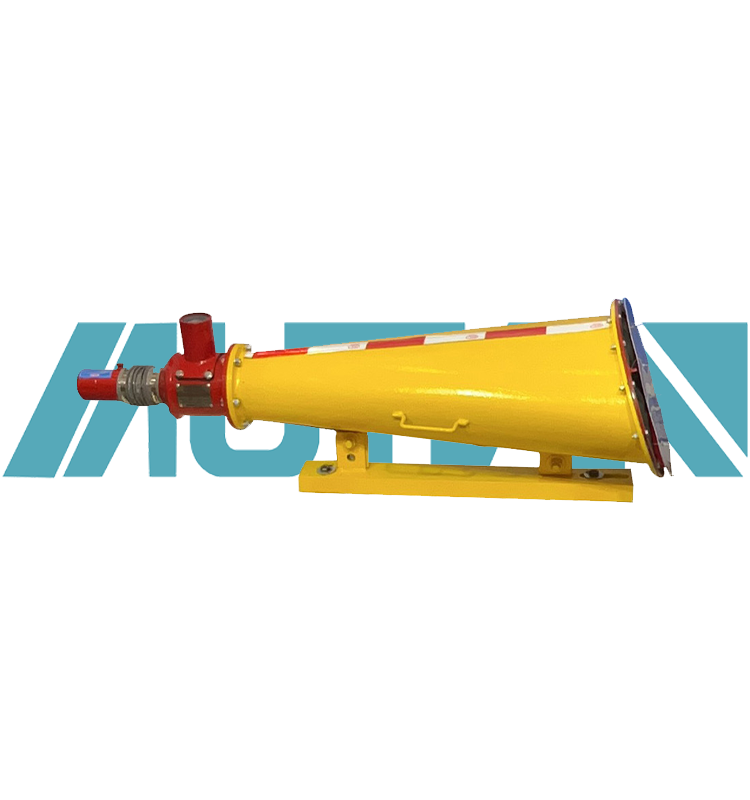

Explosion-Proof Electrical Equipment: In coal mines, electrical equipment must be designed to prevent sparks or arcs that could ignite flammable gases or dust. Automatic explosion-proof electrical devices, including switches, motors, and lighting fixtures, are constructed with sealed enclosures and specialized components to contain potential explosions and prevent ignition.

Fire Suppression Systems: Automatic fire suppression systems, such as foam or water mist systems, are installed in critical areas of coal mines to quickly extinguish fires before they escalate into explosions. These systems can be activated automatically by heat or smoke detectors or manually by personnel in emergency situations.

Emergency Communication and Evacuation Systems: In the event of an explosion or other emergency, automatic communication systems can alert mine workers to evacuate to safety zones and provide instructions for response procedures. These systems may include alarms, sirens, and voice communication devices distributed throughout the mine.

Remote Monitoring and Control: Advanced automatic explosion-proof devices may be equipped with remote monitoring and control capabilities, allowing mine operators to monitor conditions in real-time from a central control room. Remote control features enable rapid response to detected hazards and facilitate coordination of emergency procedures.

Regular Maintenance and Testing: To ensure the reliability of automatic explosion-proof devices, regular maintenance, and testing are essential. Scheduled inspections, calibration of sensors, and functional tests should be performed according to manufacturer recommendations and regulatory requirements.

In summary, automatic explosion-proof devices are indispensable safety measures in coal mines, providing continuous monitoring, detection, and mitigation of explosion hazards. By employing these devices effectively, mine operators can minimize the risk of accidents and protect the lives of workers in challenging and potentially dangerous environments.

The main equipment produced by Hebei Makita: stage electric hoist, electric hoist, manual hoist, lever hoist, pneumatic hoist and other lifting equipment

X