中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

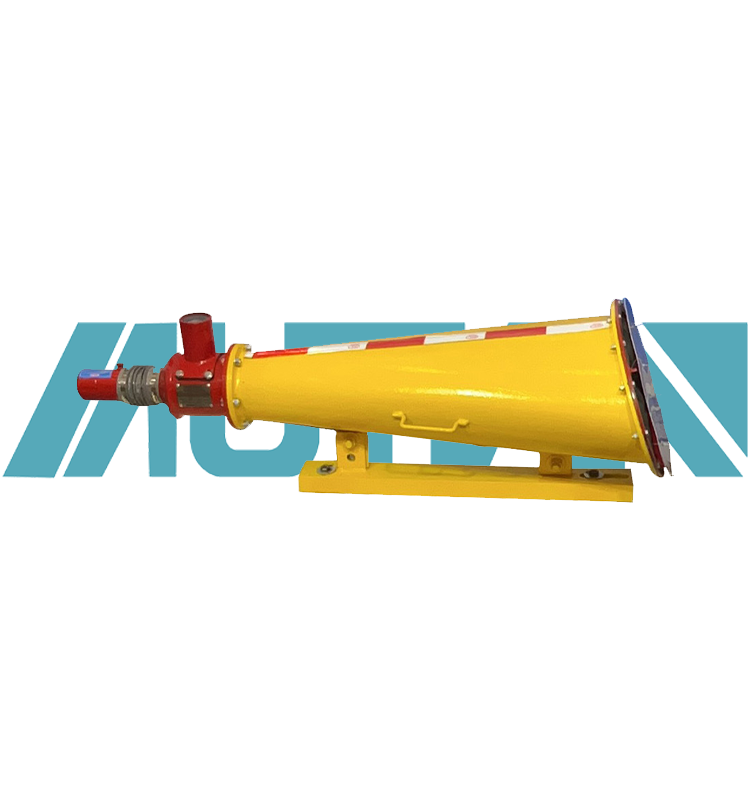

In underground coal mines, where the risk of methane gas accumulation is high, flameproof devices are essential safety measures to prevent potential explosions. Here's an introduction to flameproof devices used in coal mines:

Purpose: Flameproof devices are designed to contain any potential ignition sources within a robust enclosure, preventing them from igniting flammable gases, such as methane, that may be present in underground coal mines. These devices provide a critical layer of protection to safeguard miners and equipment against the risk of explosions.

Enclosures: Flameproof enclosures are constructed from durable materials, such as cast iron or aluminum alloy, with thick walls that can withstand high-pressure explosions. These enclosures are designed to contain any explosion that occurs within them, preventing flames, sparks, and hot gases from escaping into the surrounding atmosphere.

Certification: Flameproof devices must undergo rigorous testing and certification by regulatory authorities, such as the Mine Safety and Health Administration (MSHA) in the United States, to ensure they meet stringent safety standards. Certification typically involves testing the enclosure's ability to withstand pressure and contain explosions.

Components: Flameproof devices may include various electrical components, such as motors, switches, lighting fixtures, and control panels, which are housed within the flameproof enclosures. These components are specially designed and tested to ensure they do not generate sparks or arcs that could ignite flammable gases.

Gas Detection: In addition to containing potential ignition sources, flameproof devices may also incorporate gas detection systems to monitor the concentration of methane and other flammable gases in the mine atmosphere. Gas detectors are typically installed in strategic locations throughout the mine to provide early warning of hazardous conditions.

Alarms and Shutdown Systems: When gas detectors detect elevated levels of methane, they can trigger alarms to alert miners to the potential danger. In some cases, flameproof devices may also be equipped with automatic shutdown systems that deactivate equipment and ventilation systems to prevent further escalation of the hazard.

Installation: Flameproof devices are installed in critical areas of the mine where the risk of methane gas accumulation is highest, such as ventilation ducts, headings, and other confined spaces. Proper installation and maintenance of these devices are essential to ensure their effectiveness in preventing explosions.

Training: Miners and other personnel working in underground coal mines receive training on the proper use and operation of flameproof devices, as well as emergency response procedures in the event of a gas-related incident. Training ensures that workers are aware of the risks associated with methane gas and know how to respond effectively to mitigate those risks.

In summary, flameproof devices are integral components of safety systems in underground coal mines, providing critical protection against the hazards associated with methane gas accumulation. These devices help create safer working environments for miners and reduce the risk of explosions and other accidents.

The main equipment produced by Hebei Makita: stage electric hoist, electric hoist, manual hoist, lever hoist, pneumatic hoist and other lifting equipment

X