中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

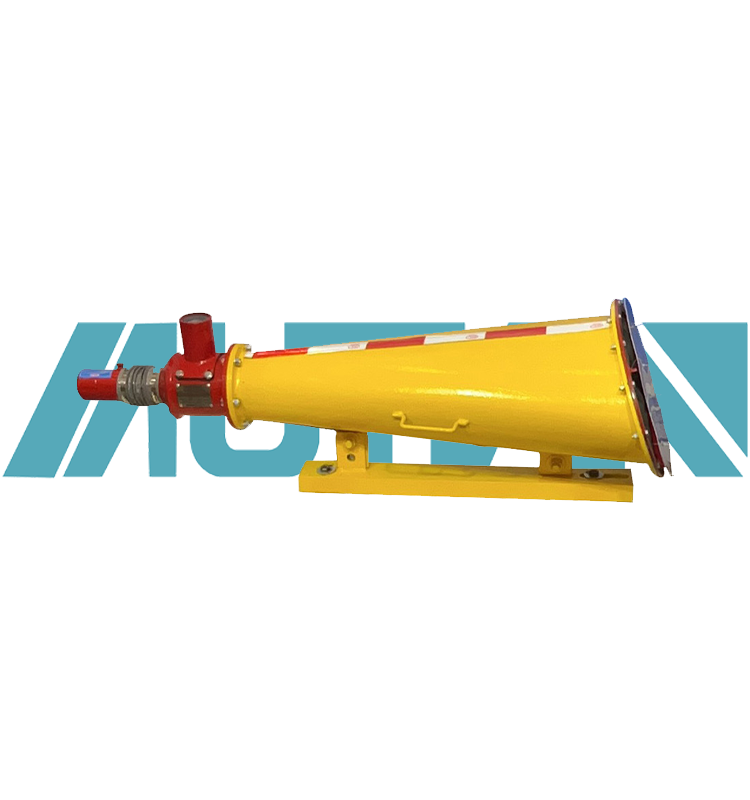

Automatic explosion-proof devices are typically constructed using specialized materials and components that are specifically designed to contain explosions and prevent the ignition of combustible gases or dust. The specific materials used may vary depending on the type and purpose of the device, as well as the requirements of relevant safety standards and regulations. However, common materials and design features found in automatic explosion-proof devices include:

Enclosures: Enclosures for explosion-proof devices are typically made from sturdy materials such as cast aluminum, stainless steel, or reinforced plastics. These materials are chosen for their durability and ability to withstand the forces generated by an explosion without rupturing or allowing flames to escape.

Seals and Gaskets: Seals and gaskets are used to ensure that explosion-proof enclosures remain tightly sealed, preventing the ingress of flammable gases or dust. These seals are often made from materials such as silicone, neoprene, or fluorinated elastomers, which offer excellent chemical resistance and resilience to high temperatures.

Specialized Components: Components within explosion-proof devices, such as switches, connectors, and wiring, are selected for their ability to prevent sparks or arcs that could ignite explosive atmospheres. These components may be coated or encapsulated with insulating materials or housed within sealed chambers to minimize the risk of ignition.

Explosion-Proof Venting: In some cases, explosion-proof devices incorporate venting mechanisms designed to safely release pressure in the event of an explosion without allowing flames or hot gases to escape. Venting materials may include flame arrestors or pressure-relief valves made from heat-resistant metals or ceramics.

Heat-Resistant Materials: Components exposed to high temperatures during normal operation or in the event of an explosion may be constructed from heat-resistant materials such as ceramics, refractory metals, or heat-resistant plastics. These materials help to ensure the integrity of the device under extreme conditions.

Corrosion Resistance: In environments where corrosion is a concern, such as coal mines with high humidity or exposure to corrosive substances, explosion-proof devices may incorporate materials with enhanced corrosion resistance, such as stainless steel or specialized coatings.

Overall, the materials used in automatic explosion-proof devices are carefully selected to withstand the harsh conditions found in hazardous environments and to ensure the reliable performance of the device in preventing explosions and protecting personnel and equipment from harm.

The main equipment produced by Hebei Makita: stage electric hoist, electric hoist, manual hoist, lever hoist, pneumatic hoist and other lifting equipment

X