中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

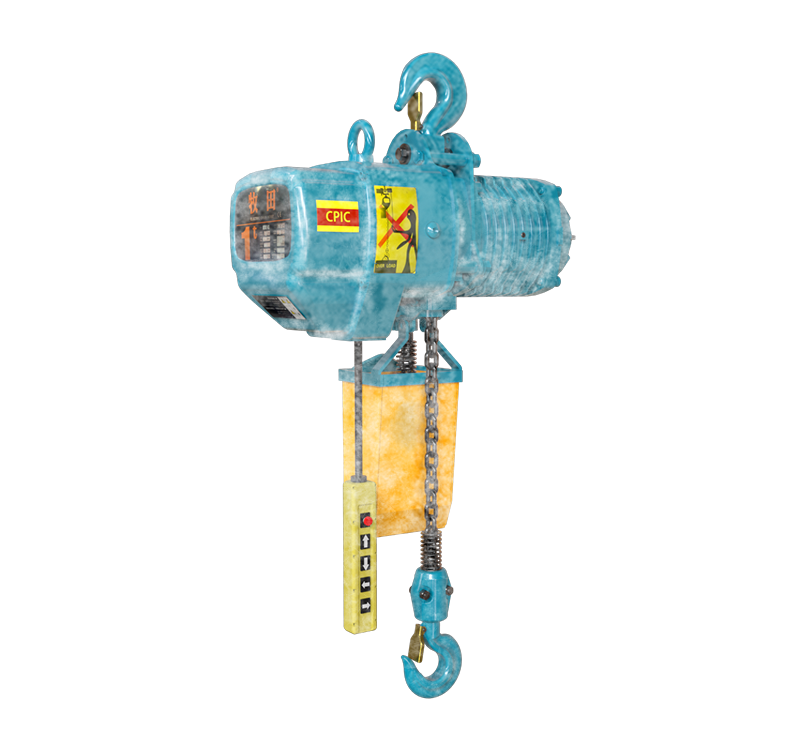

The internal structure of a low-temperature-resistant electric hoist is designed to withstand extreme cold conditions and maintain reliable operation in freezing environments. While specific designs may vary among manufacturers, here are some common features and components found in the internal structure of a low-temperature-resistant electric hoist:

Motor:

The electric hoist is equipped with a motor that is specially designed to operate in low temperatures. The motor may include features such as insulation to prevent freezing, low-temperature lubrication, and materials that maintain flexibility in cold conditions.

Gearbox:

The gearbox contains gears and transmission components that facilitate the conversion of the motor's rotational motion into the lifting motion of the hoist. Components within the gearbox are designed to withstand low temperatures, and lubrication is selected for its ability to remain effective in cold environments.

Load Chain or Wire Rope:

The load-carrying component, whether it's a load chain or wire rope, is designed to operate in low temperatures without becoming brittle. Specialized materials and coatings may be used to ensure flexibility and strength in freezing conditions.

Brake System:

The hoist is equipped with a braking system to control the descent of the load and hold it in place when the motor is not running. The brake system is designed to function effectively in low temperatures.

Control System:

The control system includes components such as contactors, relays, and circuitry. These components are selected or designed to maintain their electrical properties in cold conditions. The control system may also include low-temperature-resistant insulation.

Housing and Enclosures:

The housing and enclosures of the electric hoist are designed to provide protection against the elements, including moisture and ice. They are often sealed and insulated to prevent the ingress of water and to maintain the internal temperature.

Insulation:

Insulating materials are used throughout the hoist to prevent heat loss and maintain the temperature of critical components. This insulation helps prevent freezing and ensures the proper functioning of the hoist in cold environments.

Heating Elements:

Some low-temperature-resistant electric hoists may incorporate heating elements strategically placed to prevent the accumulation of ice or frost on critical components. This helps maintain the hoist's performance by preventing freezing.

Seals and Gaskets:

Seals and gaskets are used to create a barrier against moisture, dust, and other environmental elements. They are designed to remain flexible and effective in low temperatures.

Temperature Sensors:

Temperature sensors may be integrated into the hoist to monitor the ambient temperature. These sensors can trigger certain features, such as heating elements, to activate when temperatures drop below a specified threshold.

It's important to note that the specific design and features of a low-temperature-resistant electric hoist can vary between manufacturers. Users should consult the manufacturer's documentation and specifications to understand the capabilities and limitations of a particular hoist model in cold environments. Regular maintenance, adherence to operating guidelines, and compliance with safety standards are essential to ensure the reliable performance of the hoist in extreme cold conditions.

You

What are the advantages of low temperature resistant electric hoists compared to other low temperature resistant hoists?

ChatGPT

ChatGPT

Low-temperature-resistant electric hoists offer specific advantages in freezing environments compared to other types of hoists designed for low-temperature conditions. Here are some key advantages:

Electrical Operation:

Low-temperature-resistant electric hoists operate using an electric motor, eliminating the need for manual operation. This provides convenience and efficiency, especially in applications where frequent lifting and positioning are required.

Precise Control:

Electric hoists offer precise control over lifting, lowering, and positioning of loads. Operators can easily control the hoist with accuracy, making them suitable for applications that require careful handling of loads in cold conditions.

Variable Speeds:

Electric hoists often feature variable speed controls, allowing operators to adjust the lifting and lowering speeds according to the specific requirements of the task. This flexibility is beneficial in applications with varying load sizes and weights.

Higher Lifting Capacities:

Electric hoists are available in a range of lifting capacities, including high-capacity models. This makes them suitable for lifting heavy loads in cold environments, such as construction sites, manufacturing facilities, and industrial operations.

Continuous Operation:

Electric hoists can operate continuously for extended periods, making them suitable for applications with high lifting frequency and prolonged use. This continuous operation capability is advantageous in situations where efficiency and productivity are crucial.

Automation Compatibility:

Electric hoists can be integrated into automated systems and processes, enhancing overall workflow efficiency. They can be equipped with control interfaces compatible with automation and remote control systems.

Reduced Physical Strain:

In comparison to manual hoists, electric hoists reduce the physical strain on operators. This is especially important in cold environments, where manual operation may be challenging due to bulky clothing and the need for precise control.

Safety Features:

Electric hoists often come equipped with safety features such as overload protection, emergency braking, and limit switches. These features contribute to safer operation in low-temperature conditions.

Customizable Configurations:

Electric hoists are available in various configurations, including single-speed or dual-speed options, different power supply options, and diverse mounting options. This allows users to choose a hoist that best suits their specific application requirements.

Adaptability to Specialized Environments:

Low-temperature-resistant electric hoists are designed to operate in extremely cold conditions, offering reliability and performance in harsh environments. Their construction and features are specifically tailored to withstand freezing temperatures.

While low-temperature-resistant electric hoists have these advantages, it's essential to consider the specific requirements of the application and the environmental conditions. Users should also follow the manufacturer's guidelines for proper operation, maintenance, and safety to ensure the longevity and optimal performance of the hoist in low-temperature environments.

X