中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

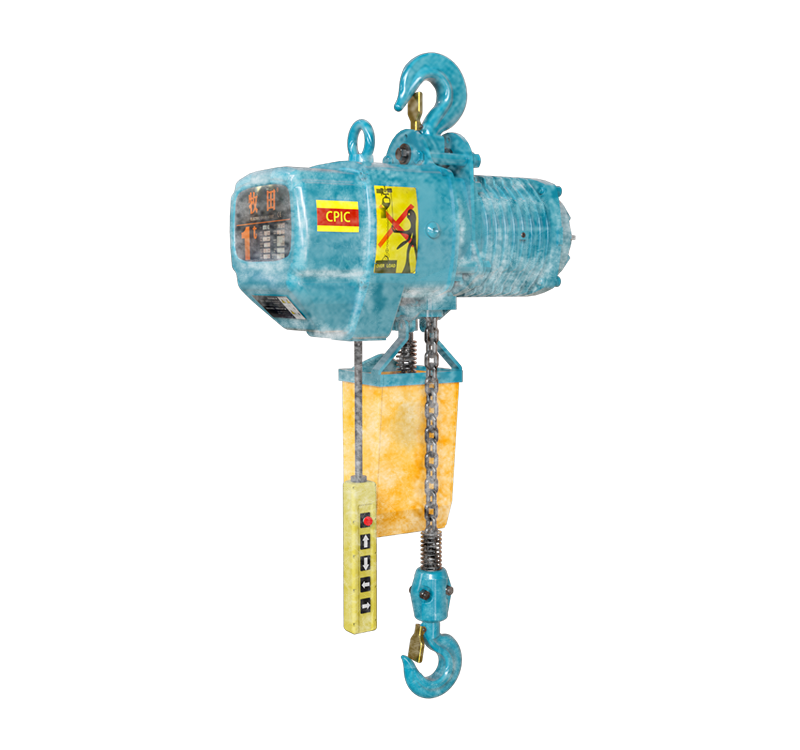

The use of low-temperature electric hoists in cold environments comes with certain risks and challenges. It's important to be aware of these factors to ensure the safe and reliable operation of the hoist. Some of the potential risks associated with the use of low-temperature electric hoists include:

Material Brittleness:

In extremely low temperatures, materials such as metals and plastics can become brittle. This may affect the structural integrity of components, leading to increased susceptibility to breakage or failure.

Reduced Lubrication Effectiveness:

Cold temperatures can affect the performance of lubricants, causing them to become more viscous or solidify. This can lead to increased friction, wear, and potential damage to moving parts if the lubrication is not effective.

Seal and Gasket Issues:

Seals and gaskets may lose their flexibility and effectiveness in extremely cold conditions. This could result in the ingress of moisture, ice, or contaminants into critical components, affecting the hoist's performance.

Electrical Component Challenges:

Cold temperatures can impact the conductivity of electrical components. Wiring, connectors, and other electrical elements may become more rigid, affecting the flow of electricity and potentially causing electrical issues.

Reduced Impact Resistance:

Materials may experience reduced impact resistance in cold conditions. In the event of a sudden shock or impact, components may be more prone to damage.

Potential for Ice Formation:

Ice accumulation on critical components, such as load chains, wire ropes, or pulleys, can impede the movement of the hoist and compromise its safe operation.

Operator Safety Concerns:

Cold weather can pose risks to the operators themselves. Prolonged exposure to extremely low temperatures can lead to issues such as frostbite or reduced dexterity, potentially impacting the safe use of controls.

To mitigate these risks and ensure the safe use of low-temperature electric hoists, consider the following measures:

Regular Maintenance: Perform regular maintenance checks, especially in harsh weather conditions, to identify and address any issues promptly.

Use of Suitable Lubricants: Ensure that the hoist is lubricated with cold-resistant lubricants recommended by the manufacturer.

Appropriate Training: Train operators on the specific challenges and safety considerations associated with using hoists in cold environments.

Monitoring and Inspection: Regularly monitor the hoist for signs of wear, damage, or ice formation, and conduct thorough inspections before each use.

Adherence to Operating Guidelines: Follow the manufacturer's guidelines and recommendations for the safe operation of the hoist in low-temperature conditions.

By taking these precautions and addressing the specific challenges associated with low-temperature environments, operators can enhance the safety and performance of electric hoists in cold conditions.

X