中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

Starting and stopping a pneumatic winch involves controlling the flow of compressed air to the winch motor. Pneumatic winches use air pressure to power the motor, and manipulating the air supply regulates the winching operation. Here are the general steps for starting and stopping a pneumatic winch:

Starting the Pneumatic Winch:

Connect Compressed Air Supply:

Ensure that the pneumatic winch is properly connected to a compressed air supply. Use appropriate hoses and fittings to connect the air source to the winch.

Check Air Pressure:

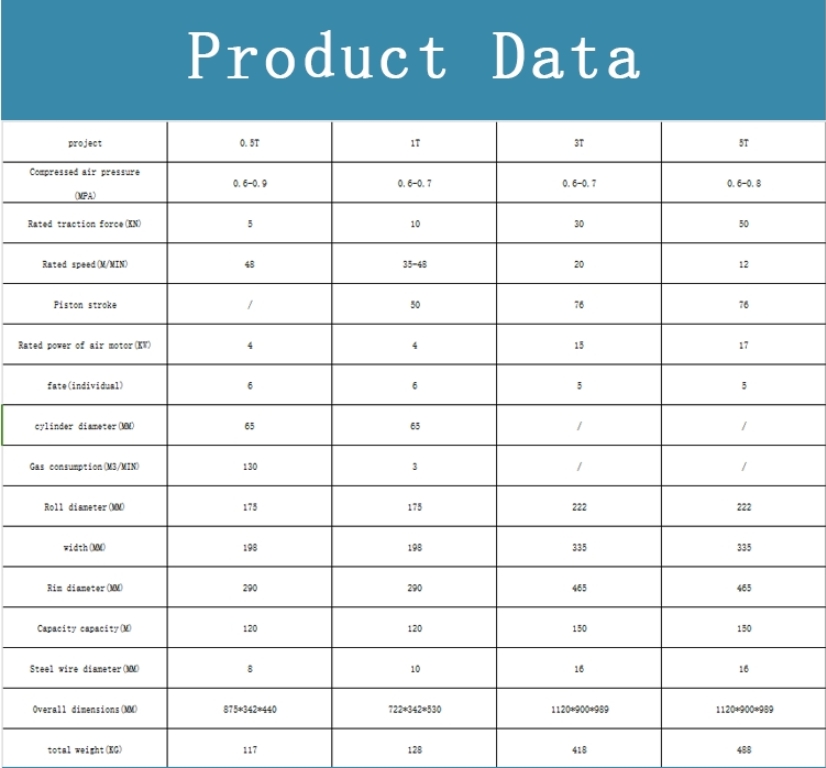

Verify that the air pressure supplied to the winch is within the specified operating range. Consult the winch's user manual or specifications for the recommended air pressure.

Engage the Air Supply:

Open the air supply valve or control on the compressed air line to allow air to flow to the winch. The winch motor should start turning once the air supply is engaged.

Control the Winching Operation:

Use the winch controls, typically provided in the form of levers or buttons on the winch itself or through a remote control, to control the winching operation. Adjust the controls to achieve the desired line speed and direction.

Monitor the Operation:

Keep an eye on the winch operation and the load being pulled. Ensure that the winch is functioning as expected and that the load is moving smoothly.

Stopping the Pneumatic Winch:

Release the Winch Controls:

If using manual controls, release the control lever or button to stop the winching operation. This action will cut off the air supply to the winch motor.

Close the Air Supply Valve:

Close the air supply valve or control on the compressed air line to stop the flow of compressed air to the winch. This will effectively stop the winch motor.

Monitor the Load:

After stopping the winch, monitor the load to ensure that it has come to a complete stop. Ensure that the load is secure and that there is no unintended movement.

Perform Post-Operation Checks:

Conduct a visual inspection of the winch and surrounding area. Check for any signs of damage, loose connections, or abnormal wear. Address any issues before the next use.

It's important to note that the specific controls and procedures may vary depending on the design and model of the pneumatic winch. Always refer to the manufacturer's instructions and guidelines for the particular winch you are using. Additionally, follow safety protocols, wear appropriate personal protective equipment, and adhere to industry standards when operating pneumatic winches. Regular maintenance and inspections contribute to the safe and efficient use of the equipment.

X