中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

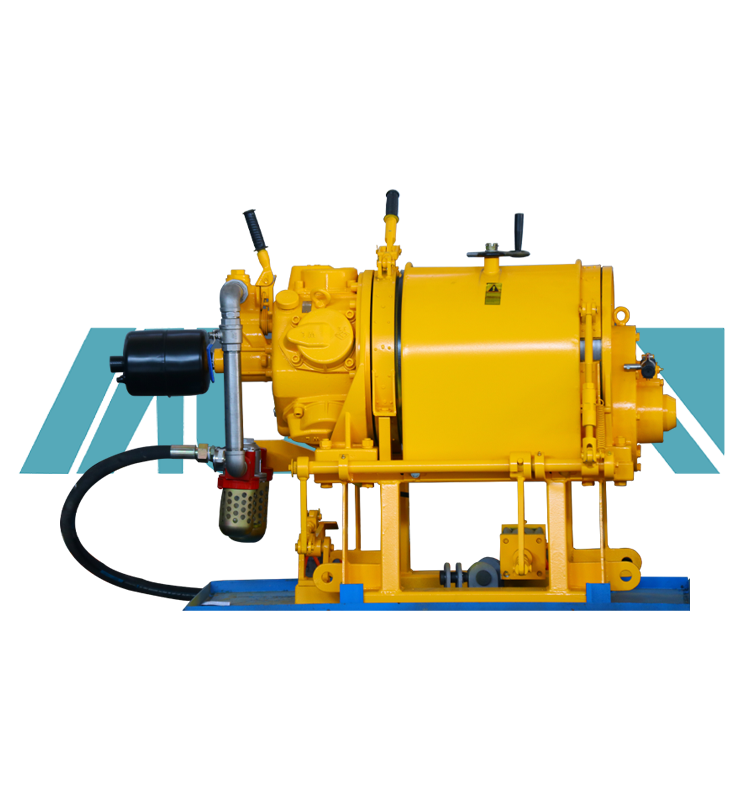

Operating a pneumatic winch involves several steps to ensure safe and efficient use. Pneumatic winches use compressed air as a power source to drive the winching mechanism. Here are general guidelines for operating a pneumatic winch:

Inspect the Winch:

Conduct a visual inspection of the pneumatic winch. Check for any visible damage, loose components, or signs of wear. Ensure that all connections are secure.

Check Air Supply:

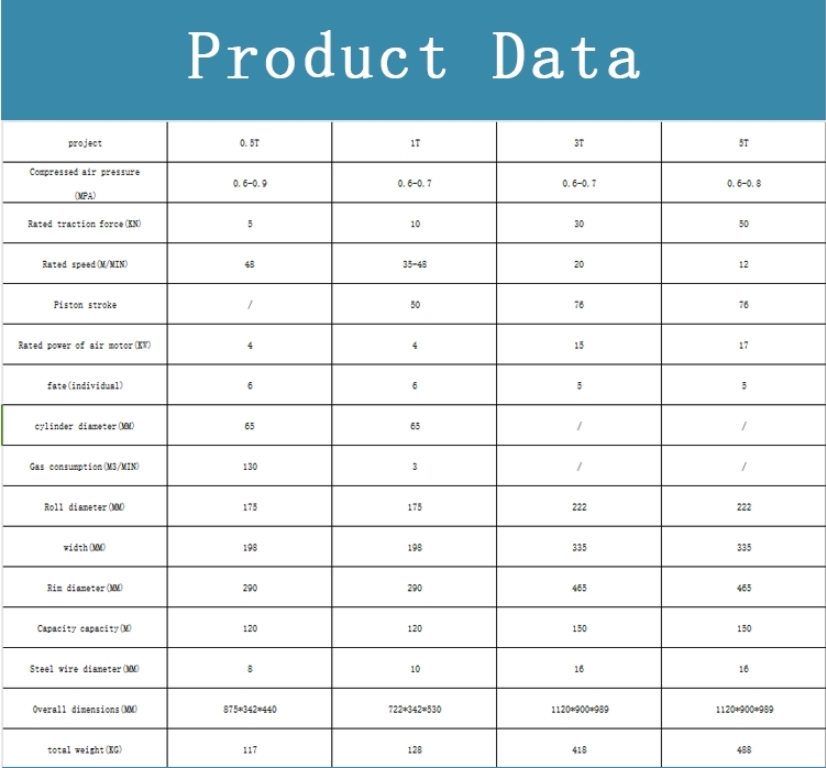

Verify that the compressed air supply is connected and at the correct pressure. Consult the winch's specifications for the recommended operating pressure.

Ensure Proper Lubrication:

Confirm that the pneumatic winch is properly lubricated. Check lubrication points and add lubricant if necessary. Proper lubrication helps maintain the efficiency and longevity of the winch.

Connect Air Supply:

Connect the compressed air supply to the pneumatic winch. Use appropriate hoses and fittings, ensuring a secure and leak-free connection.

Adjust Air Pressure:

Set the air pressure to the recommended operating pressure specified by the manufacturer. Adjust the pressure as needed for the specific winching task.

Engage Controls:

Use the winch controls to engage the winching operation. Controls may include levers, buttons, or other mechanisms for controlling the speed and direction of the winch.

Control Line Speed:

Adjust the controls to achieve the desired line speed. Some pneumatic winches offer variable speed control, allowing operators to tailor the speed to the requirements of the task.

Monitor the Operation:

Keep a close eye on the winching operation. Ensure that the load is moving smoothly and that the winch is functioning as expected. Be aware of the tension on the cable or rope.

Directional Control:

If the pneumatic winch is equipped with directional controls, use them to control the direction of the winching operation. This is crucial for tasks that require precision or changing the direction of the load.

Release Controls:

When the winching operation is complete, release the controls to stop the winch. Allow the winch drum to come to a complete stop.

Disconnect Air Supply:

Disconnect the compressed air supply from the winch. Close the air supply valve to stop the flow of compressed air.

Inspect the Winch:

Perform a post-operation inspection of the pneumatic winch. Check for any damage, wear, or issues. Address any issues before the next use.

Secure the Load:

If the load has been moved, secure it in its final position. Ensure that all equipment is properly stowed and secured.

Personal Protective Equipment (PPE):

Wear appropriate PPE, including safety glasses, gloves, and hearing protection, as needed.

Follow Manufacturer's Guidelines:

Adhere to the manufacturer's operating guidelines and recommendations specific to the pneumatic winch model.

Emergency Stop Procedures:

Familiarize yourself with the emergency stop procedures in case immediate cessation of the winching operation is necessary.

Always refer to the manufacturer's instructions and guidelines for the specific pneumatic winch you are using, as operating procedures may vary. Additionally, follow safety protocols and regulations applicable to your industry and workplace. Regular maintenance and inspections contribute to the safe and efficient use of pneumatic winches.

X