中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

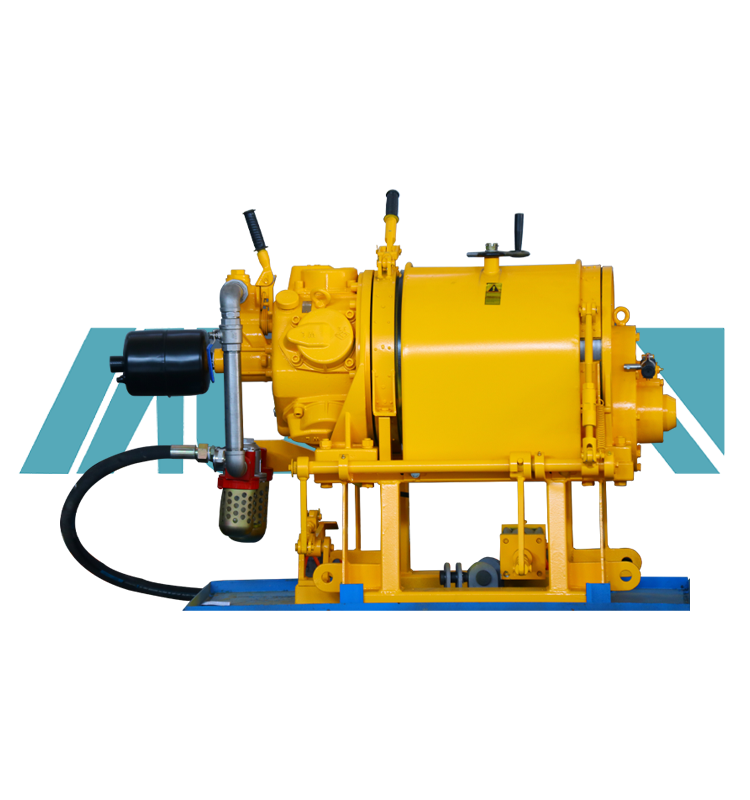

While pneumatic winches are valuable tools for various lifting and pulling applications, their use comes with certain risks that need to be addressed to ensure safety. Here are some potential risks associated with using pneumatic winches:

Air Pressure Hazards:

Pneumatic winches operate using compressed air, and there is a risk of injury if the air pressure is too high. Operators need to be aware of the recommended pressure levels and use appropriate pressure regulators to prevent overpressurization.

Air Hose Safety:

The air hoses connected to pneumatic winches can pose a tripping hazard or be subjected to damage, leading to air leaks. Proper routing and securing of hoses are crucial to prevent accidents and maintain a safe working environment.

Noise Exposure:

Pneumatic winches can generate significant noise levels during operation. Prolonged exposure to high noise levels without proper hearing protection can lead to hearing damage or impairment.

Air Quality Concerns:

In environments with poor air quality or the presence of contaminants, the use of pneumatic winches may introduce potential risks to operators. Ensuring clean and dry compressed air is essential to prevent damage to the winch and protect operators.

Overloading:

Similar to other winches, pneumatic winches have load capacities. Overloading can lead to equipment failure, causing damage to the winch and posing a risk of injury or accidents.

Entanglement Hazards:

Moving parts in the winch, such as cables or ropes, can create entanglement hazards. Operators should be cautious to avoid getting clothing, body parts, or tools caught in these moving components.

Uncontrolled Movement:

If the pneumatic winch is not properly controlled or if there is a failure in the control system, uncontrolled movement of the load or cable can occur, leading to accidents and injuries.

Failure of Braking System:

Pneumatic winches typically have braking systems to control and secure the load. If the braking system fails or malfunctions, it can result in uncontrolled descent or movement of the load.

Insufficient Training:

Inadequate training of operators increases the risk of errors and accidents. Proper training in the use of pneumatic winches, including understanding control functions, load capacities, and safety procedures, is crucial.

Environmental Conditions:

Harsh environmental conditions, such as extreme temperatures or exposure to corrosive substances, can impact the performance and safety of pneumatic winches. Operators should be aware of these conditions and take appropriate precautions.

Lack of Emergency Procedures:

In the absence of clear emergency procedures or if operators are not adequately prepared for unexpected situations, accidents can escalate, leading to injuries or damage.

Poorly Maintained Equipment:

Lack of regular maintenance can result in equipment malfunctions, decreased reliability, and increased risk of accidents. Routine inspections and maintenance are crucial for preventing issues.

To mitigate these risks, it is important to follow safety guidelines, conduct regular inspections and maintenance, provide proper training to operators, and adhere to manufacturer recommendations and industry standards. Implementing safety measures, such as using personal protective equipment, can also contribute to a safer working environment.

X