中文版

中文版

releaseTime:2024-04-01 10:00:21source:Mu TiannumberOfPageViews:0

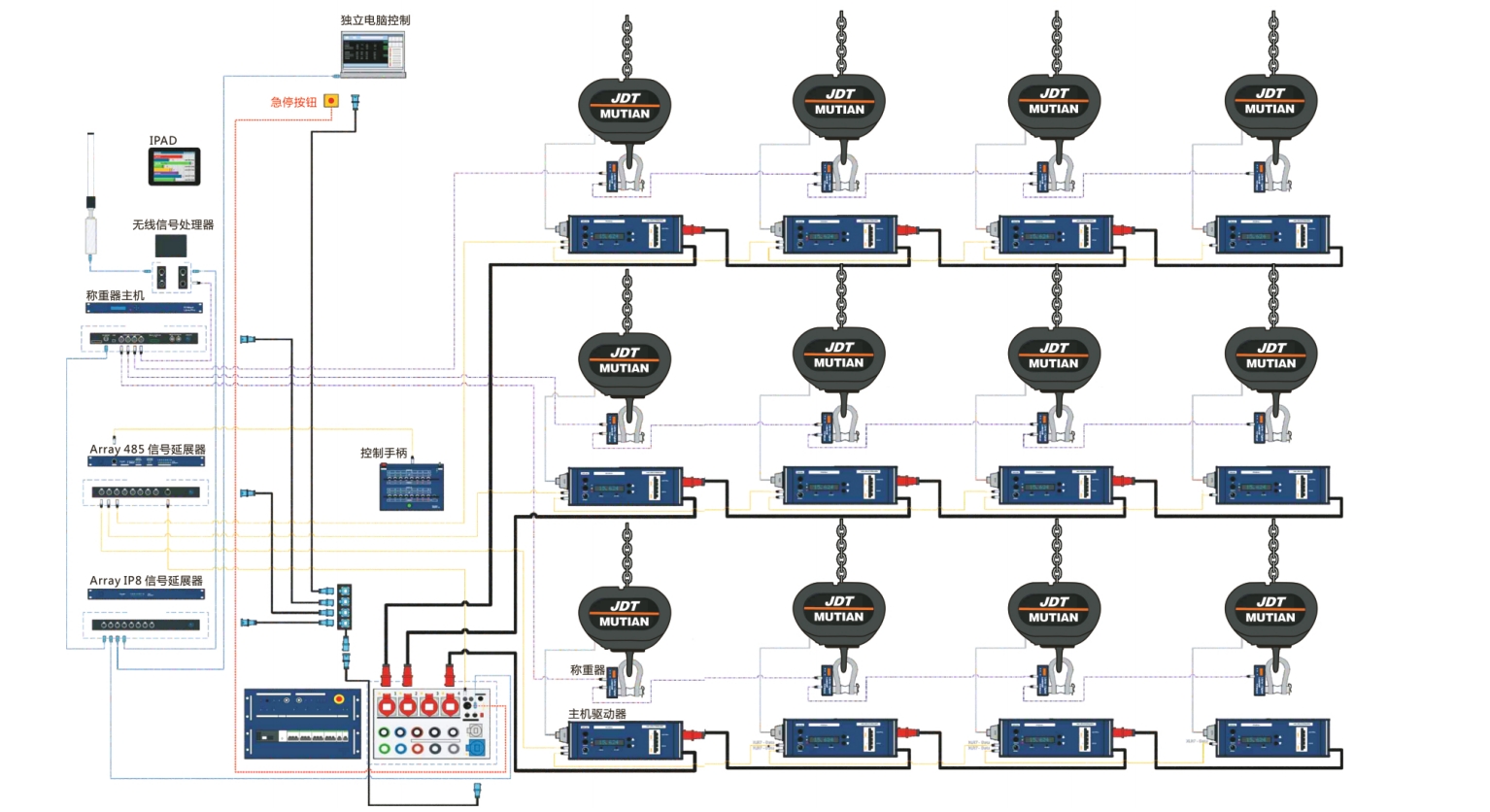

Group control in stage electric hoists allows multiple hoists to be controlled together as a single unit, rather than individually. This capability is particularly useful for scenarios where coordinated movement of multiple loads is required, such as raising or lowering a truss system, moving a scenic element, or adjusting lighting fixtures together for a specific effect. Here's how group control is typically performed:

Group Formation: Before operation, the hoists that need to be controlled together are grouped or assigned to a specific control group within the hoist control system. This grouping is usually configured through the hoist controller interface or software.

Synchronization: Once the hoists are grouped, the controller ensures that they move synchronously. This means that all hoists within the group will start, stop, and move at the same speed simultaneously, ensuring coordinated movement.

Command Input: The operator inputs commands into the hoist controller interface, specifying the desired action for the entire group of hoists. These commands may include raising, lowering, stopping, or adjusting the speed of movement.

Safety Monitoring: During group control, the controller continuously monitors the status of each hoist within the group to ensure safe operation. This includes monitoring load weights, detecting any faults or malfunctions, and implementing safety measures to prevent accidents.

Feedback and Monitoring: Many hoist control systems provide feedback mechanisms to monitor the position and status of each hoist within the group in real-time. This feedback allows operators to accurately track the movement of loads and make adjustments as needed.

Fine-tuning and Adjustment: Operators may have the option to adjust parameters such as speed, acceleration, and deceleration for the entire group of hoists to achieve precise control over movement.

Emergency Stop: In case of emergencies or safety concerns, the hoist controller should have an emergency stop function that immediately halts the movement of all hoists within the group to prevent accidents or damage.

Overall, group control in stage electric hoists provides a convenient and efficient way to manage the movement of multiple loads simultaneously, allowing for synchronized and coordinated operation in various stage and event applications.

The main equipment produced by Hebei Makita: stage electric hoist, electric chian hoist, wire rope electric hoist,manual hoist, lever hoist, pneumatic hoist and other lifting equipment