中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

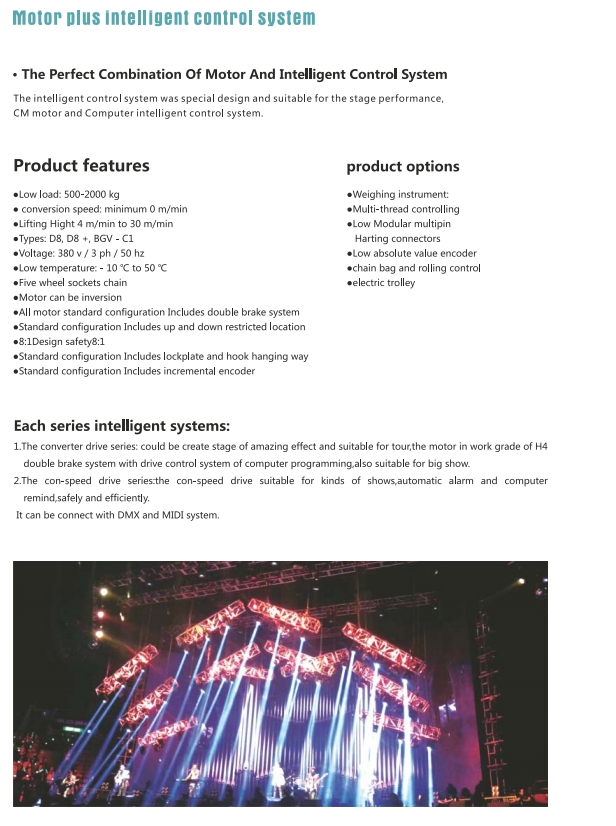

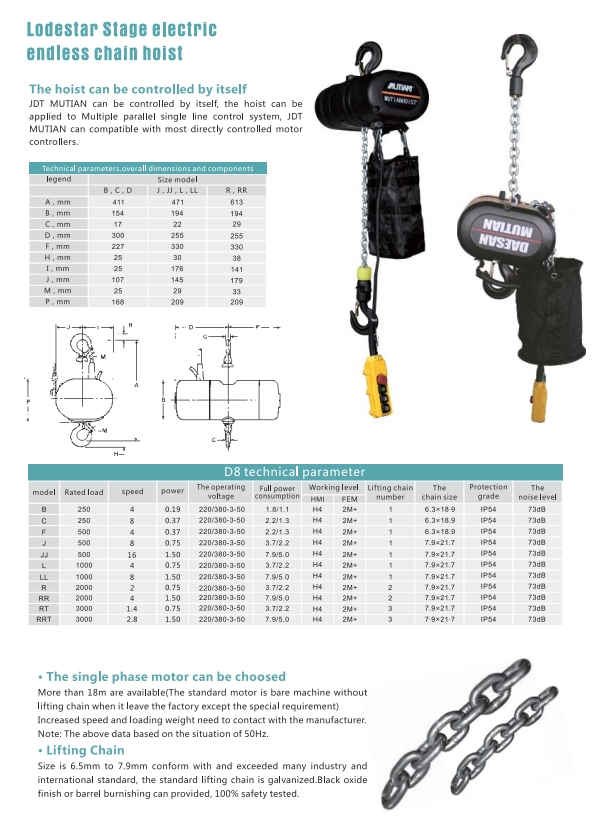

The working process of a stage electric hoist involves a series of steps to lift, lower, and move loads with precision. Here is a general overview of the working process:

Power On:

The operator powers on the electric hoist by connecting it to a power source. Electric hoists are typically powered by electricity, and the power supply activates the electric motor.

Control Activation:

The operator uses a control device, such as a pendant or remote control, to activate the hoist. The control device is equipped with buttons or switches for lifting, lowering, and stopping the hoist.

Lifting Command:

When the operator presses the lifting button on the control device, an electrical signal is sent to the hoist's electric motor. The motor starts rotating, generating mechanical power.

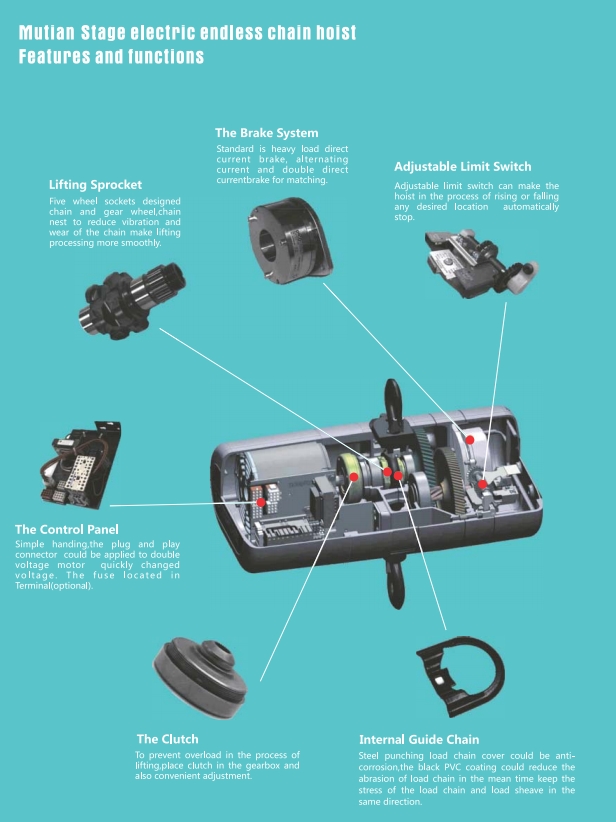

Transmission and Gearbox:

The rotating motion from the electric motor is transmitted to a gearbox or transmission system. The gearbox adjusts the speed and torque of the motor's rotation based on the design and specifications of the hoist.

Lifting Mechanism Activation:

The gearbox is connected to the hoist's lifting mechanism, which can be a drum or a chain hoist. The lifting mechanism is activated, causing the drum to rotate or the chain hoist to move, depending on the hoist's design.

Lifting Cable or Chain Movement:

As the lifting mechanism moves, it winds the lifting cable (for drum-based hoists) or lifts the chain (for chain hoists). The load attached to the cable or chain is lifted off the ground.

Precision Control:

The operator has precise control over the lifting process using the control device. The speed and direction of the hoist's movement can be adjusted to achieve the desired positioning of the load.

Limit Switches:

Limit switches are integrated into the hoist to set upper and lower travel limits. These switches automatically stop the hoist when the load reaches the desired height or lowers to the lowest point, preventing overtravel.

Brake Engagement:

When the lifting command is stopped, the hoist's brake system engages to hold the load securely in place. The brake prevents unintended movement when the motor is not running.

Lowering Command:

If the operator wants to lower the load, they press the lowering button on the control device. The electric motor rotates in the opposite direction, and the hoist's brake system releases to allow controlled lowering.

Emergency Stop (if needed):

In case of an emergency or if an immediate halt is required, the operator can use the emergency stop button on the control device. This quickly stops all hoist movements.

Power Off:

Once the lifting or lowering process is complete, the operator powers off the electric hoist, disconnecting it from the power source.

This working process allows stage electric hoists to provide controlled and precise movements, making them essential for lifting and positioning loads in the entertainment and event industry. The specific details of the working process may vary depending on the design and features of the electric hoist.

X