中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

The internal structure of a truss electric hoist consists of several key components that work together to enable the lifting and lowering of loads in various applications. While specific designs may vary among manufacturers and models, the following are common internal components found in a truss electric hoist:

Motor:

The electric motor is a crucial component that provides the power to drive the hoist. It converts electrical energy into mechanical power to operate the lifting mechanism.

Gearbox:

The gearbox is responsible for adjusting the speed and torque of the electric motor's output. It ensures that the hoist operates at the desired lifting speed and with sufficient power.

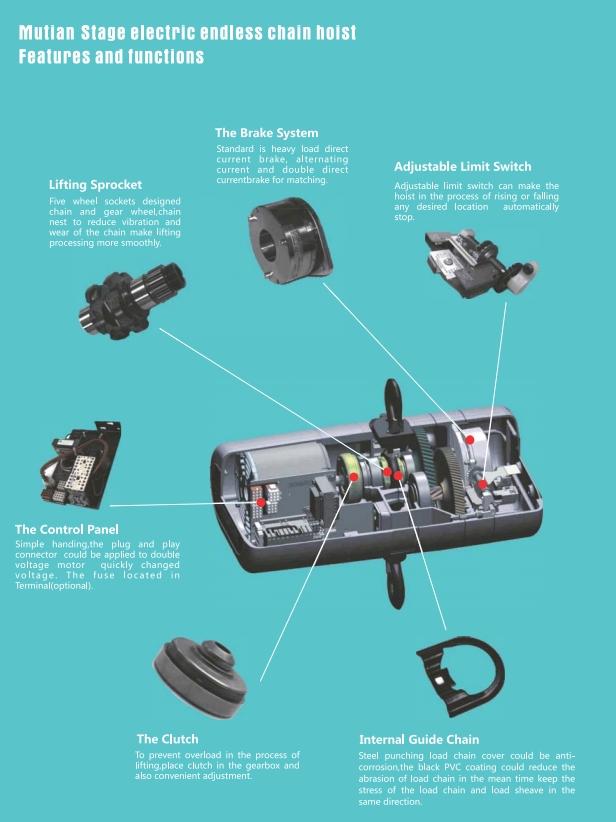

Brake System:

The brake system is essential for stopping the motion of the load when required. It prevents the load from drifting when the hoist is not actively lifting or lowering.

Lifting Mechanism:

The lifting mechanism includes components such as load chains, load hooks, and the hoist frame. The load chains are guided by the hoist's lifting mechanism to raise and lower the load.

Load Chain:

The load chain is a load-bearing component that is wound around a lifting drum. It is designed to support and lift the load. The material of the load chain is typically high-strength alloy steel.

Load Hook:

Load hooks are attached to the load chain and provide the connection points for securing the load. They are designed to safely support the weight of the load without deformation or failure.

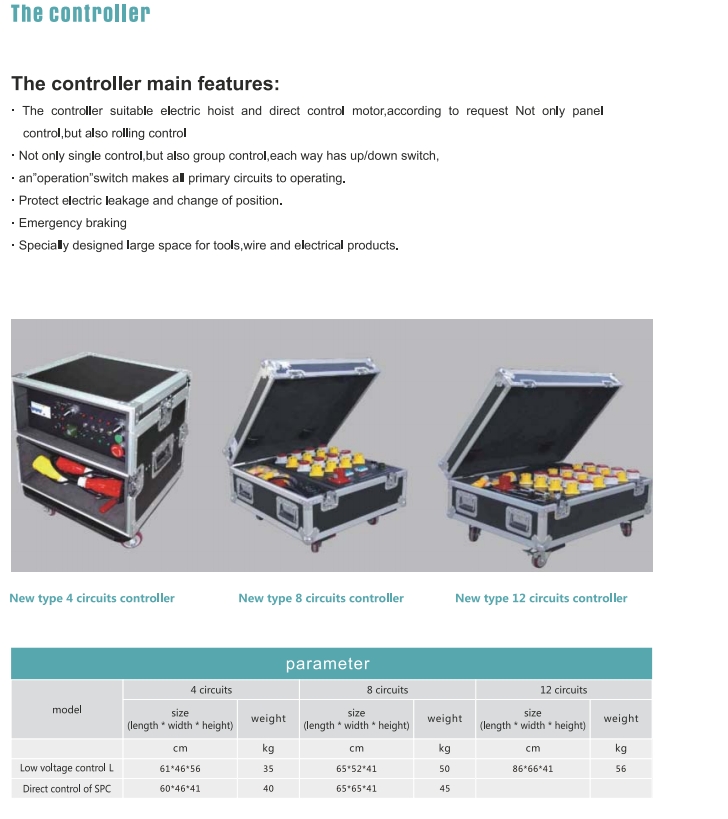

Control System:

The control system includes the hoist controller, which is the interface for the operator to control the lifting and lowering operations. It may feature buttons or levers for various functions, including raising, lowering, and emergency stopping.

Limit Switches:

Limit switches are safety devices that prevent the hoist from overtraveling in either the up or down direction. They are crucial for preventing damage to the hoist and ensuring safe operation.

Overload Protection:

Overload protection systems are designed to prevent the hoist from lifting loads beyond its rated capacity. This is a safety feature to protect both the equipment and the operator.

Electrical Components:

Various electrical components, such as wiring, sensors, and connectors, are integrated into the hoist for proper electrical functioning. These components are designed to operate safely and reliably.

Shell (Housing):

The shell or housing encases the internal components and provides protection from external elements. It is typically made from materials such as aluminum or steel, providing durability and protection.

It's important to note that the internal structure may vary based on the design and specifications of the truss electric hoist. Users should refer to the manufacturer's documentation for detailed information on the internal components, maintenance procedures, and safety guidelines specific to a particular model.

X