中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

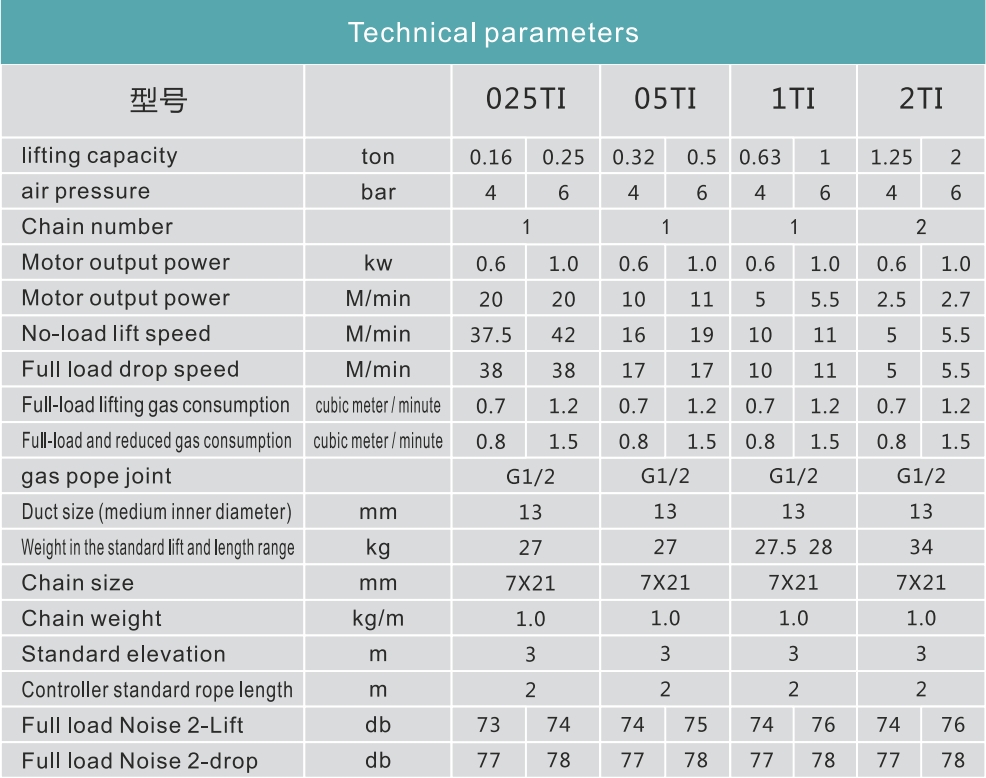

Pneumatic hoist is a lifting equipment that uses compressed air as the power source to drive internal mechanical components to lift heavy objects.

It is composed of a lifting mechanism, a walking mechanism, and a gas distribution system, which has the characteristics of high frequency, stepless speed change, explosion-proof performance, and high safety factor.

Pneumatic hoists are commonly used in three types: blade type, piston type, and cylinder type, and are widely used in non sparking workplaces such as petroleum, chemical plants, pharmaceutical factories, coal mines, textiles, warehousing, textiles, spray painting, logistics, docks, etc.,

which are flammable, explosive, high-temperature, high dust, and highly corrosive.

When using pneumatic hoists, there are some precautions to follow.

For example, it is not allowed to lift and unload heavy objects on the side, and overload use is prohibited;

There should be no obstacles within the walking range of the operator and on the route through which heavy objects pass;

Keep hands and rags away from rotating parts;

In daily work, it is not allowed to manually use a limiter to stop lifting heavy objects or stopping equipment operation;

The manual buttons should move accurately and sensitively in the up and down, left and right directions, and the motor and reducer should have no abnormal sound;

Special maintenance personnel should be assigned to inspect the main performance and safety status of the electric hoist once a week, and promptly eliminate any faults found.

After completing the work, remember to turn off the main power switch and cut off the main power supply.

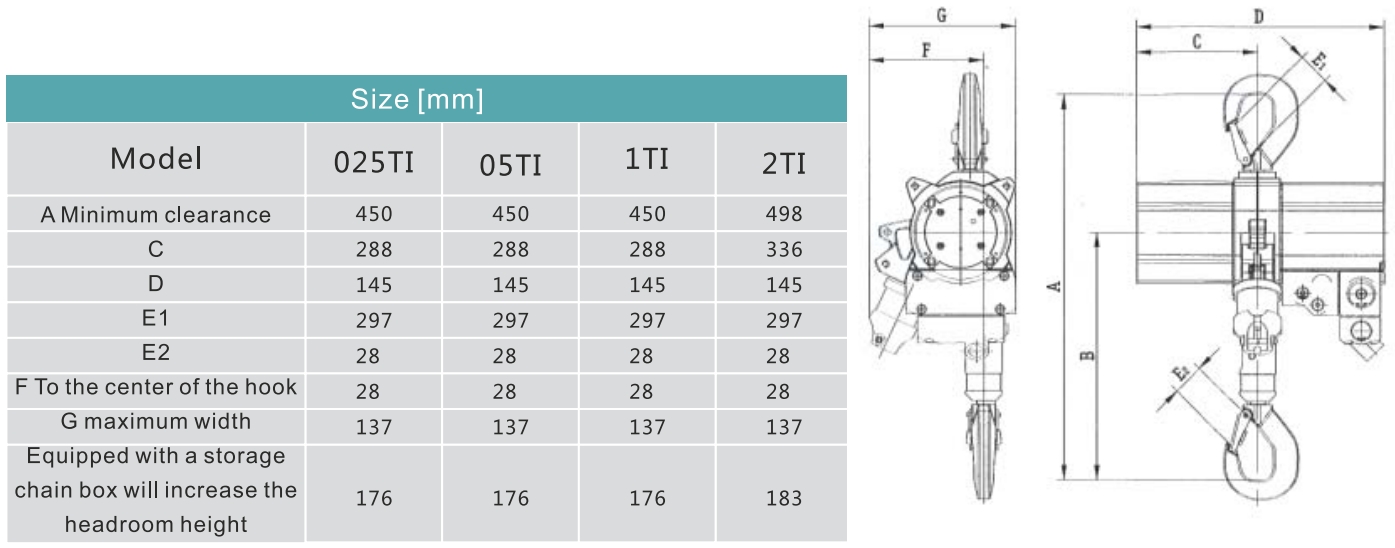

Please select the appropriate pneumatic hoist model and specification based on the actual working environment and needs, and strictly follow the instructions for use

X