中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

A pneumatic balancer is a type of material handling equipment that uses compressed air to balance and manipulate the weight of loads, making it easier for operators to lift, position, and move heavy objects. These devices are designed to provide ergonomic assistance in various industrial applications, reducing the physical strain on workers and improving overall efficiency.

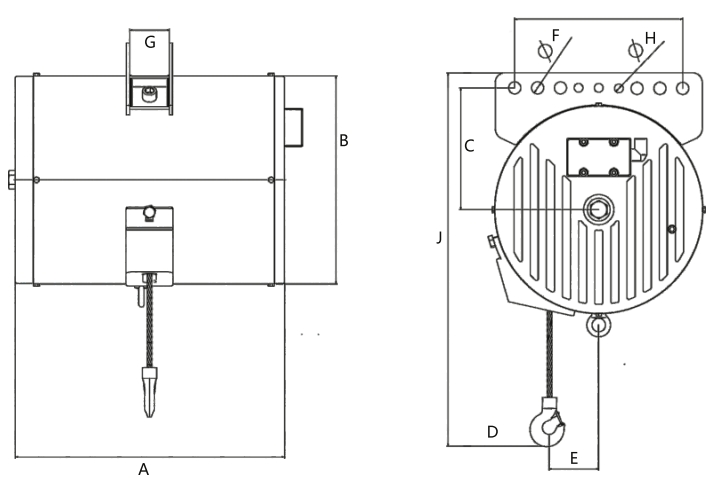

The basic principle behind pneumatic balancers involves using a pneumatic cylinder, which is powered by compressed air, to counterbalance the weight of the load. The device typically consists of a suspended tool or load attached to a pneumatic balancing system. The system includes a piston or cylinder that moves up and down in response to changes in the load's position. As the load is lifted or lowered, the pneumatic balancer adjusts the air pressure to maintain equilibrium, effectively neutralizing the gravitational forces acting on the load.

Pneumatic balancers are commonly used in assembly lines, manufacturing plants, and other industrial settings where repetitive lifting and positioning tasks are required. They contribute to improved worker safety, increased productivity, and reduced fatigue by providing consistent support for loads of varying weights. Additionally, these devices often come with control features that allow operators to precisely control the movement of the load with minimal effort.

X