中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

While portable manual workshop winches are useful tools for lifting, pulling, and positioning loads in various applications, it's important to be aware of potential risks associated with their use. Understanding these risks can help users implement safety measures and precautions to mitigate potential hazards. Here are some common risks associated with portable manual workshop winches:

Overloading:

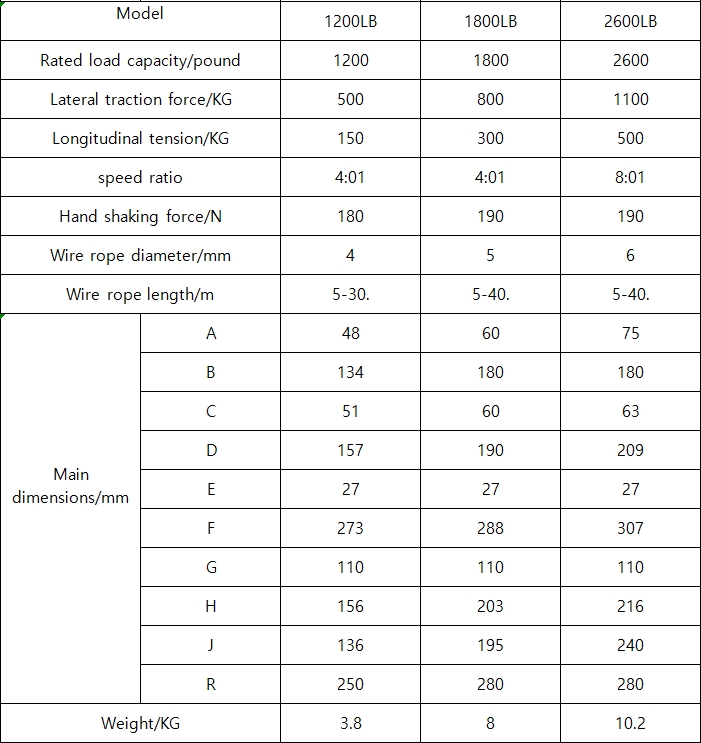

One of the primary risks is overloading the winch beyond its rated capacity. Exceeding the maximum load capacity can lead to equipment failure, damage to the winch, and pose a serious safety risk to the operator and nearby personnel.

Inadequate Anchoring:

A secure and stable anchoring point is essential for the safe operation of manual winches. If the winch is not anchored properly, it can result in unexpected movement, loss of control, and potential accidents.

Cable or Rope Failure:

The cable or rope used with the winch may deteriorate over time due to wear, abrasion, or exposure to harsh conditions. A damaged or weakened cable poses a significant risk of snapping, causing injury or damage.

Insufficient Inspection and Maintenance:

Neglecting regular inspection and maintenance of the winch can lead to the accumulation of wear and tear, reducing its effectiveness and safety. Lubrication, checking for damaged components, and ensuring proper functionality are critical for safe operation.

Lack of Training:

Operating a manual winch requires knowledge of its features, limitations, and safe practices. Inadequate training can lead to improper use, increasing the risk of accidents and injuries.

Inadequate Personal Protective Equipment (PPE):

Users should wear appropriate personal protective equipment, such as gloves and safety glasses, when operating a manual winch. Failure to use PPE can result in hand injuries, eye injuries, or other hazards.

Uncontrolled Load Movement:

If the load being lifted or pulled is not properly controlled, it can swing or shift unexpectedly, posing a risk of crushing, pinching, or striking hazards to operators and bystanders.

Operator Fatigue:

Manual winches rely on the physical strength and endurance of the operator. Prolonged or repetitive use can lead to operator fatigue, reducing alertness and increasing the likelihood of errors or accidents.

Environmental Conditions:

Adverse environmental conditions, such as rain, snow, or high winds, can impact the safe operation of manual winches. Slippery surfaces or reduced visibility can contribute to accidents if proper precautions are not taken.

Improper Rigging and Attachment:

Incorrect rigging or attachment of the load to the winch can result in instability and failure during operation. It is crucial to follow proper rigging procedures and use appropriate attachments to ensure load stability.

Failure to Follow Manufacturer's Guidelines:

Ignoring or deviating from the manufacturer's guidelines, instructions, and recommendations for the use of the manual winch can lead to unsafe conditions and equipment failure.

To minimize these risks, users should adhere to the following safety practices:

Read and follow the manufacturer's instructions and guidelines.

Conduct regular inspections and maintenance of the winch and associated components.

Ensure proper anchoring and rigging.

Use appropriate personal protective equipment.

Provide adequate training for operators.

Avoid overloading the winch.

Be mindful of environmental conditions.

Take breaks to prevent operator fatigue.

Implement proper load control measures.

By addressing these risks and following safety precautions, users can enhance the safe and effective use of portable manual workshop winches in various applications.

X