中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

The usage time of an electronic crane scale refers to its operational lifespan, and several factors can influence how long a crane scale remains in service. Here are key considerations affecting the usage time of electronic crane scales:

Quality and Durability:

The quality and durability of the electronic crane scale play a significant role in determining its operational lifespan. High-quality scales made with robust materials are likely to have a longer service life.

Maintenance Practices:

Regular maintenance is crucial for extending the operational lifespan of electronic crane scales. Proper cleaning, calibration, and routine inspections can help identify and address issues before they become serious problems.

Environmental Conditions:

The operating environment significantly impacts the lifespan of electronic crane scales. Scales used in harsh conditions, such as extreme temperatures, high humidity, or exposure to corrosive substances, may experience more wear and require more frequent maintenance.

Overloading and Misuse:

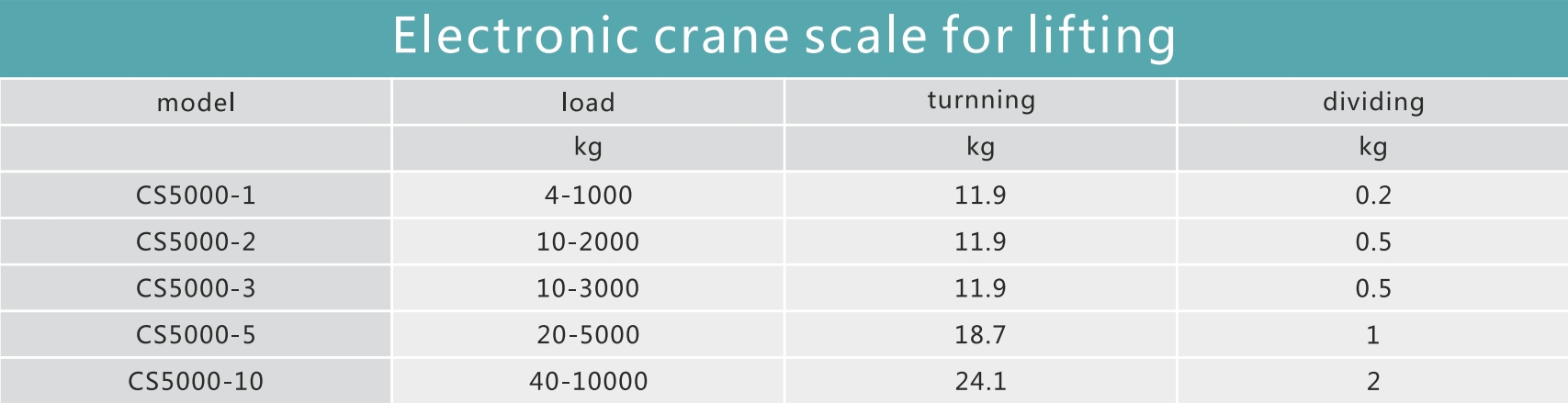

Overloading the scale beyond its rated capacity or subjecting it to misuse can lead to premature wear and damage. Following the manufacturer's guidelines for load capacity and proper usage helps prevent unnecessary strain on the scale.

Manufacturer's Design and Build Quality:

The design and build quality of the electronic crane scale, as determined by the manufacturer, influence its overall durability. Scales from reputable manufacturers with a focus on quality construction are more likely to have a longer operational lifespan.

Technology Advances:

Advances in technology may result in newer and more sophisticated models with improved features and capabilities. While older models may still function, users might choose to upgrade to newer versions to benefit from enhanced performance and features.

Type of Load Handling:

The frequency and type of loads handled by the crane scale can impact its usage time. Scales used for heavy or frequent lifting operations may experience more wear and tear compared to those used infrequently or for lighter loads.

User Training:

Proper training of operators in the correct usage of the electronic crane scale can contribute to its longevity. Misuse, mishandling, or incorrect attachment procedures can lead to damage.

Availability of Replacement Parts:

The availability of replacement parts for maintenance and repairs is a factor in determining the extended usage time. If replacement parts are readily available, it may be possible to address issues and extend the life of the scale.

Regulatory Compliance:

Compliance with industry regulations and standards is important. Adhering to safety guidelines and requirements helps ensure that the crane scale is used within specified parameters, contributing to its safe and prolonged use.

It's essential for users to follow the manufacturer's guidelines, conduct regular inspections, and perform necessary maintenance to maximize the operational lifespan of electronic crane scales. As technology evolves, users may choose to upgrade their equipment to take advantage of improved features and capabilities.

X