中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

A lever manual hoist, also known as a lever chain hoist or ratchet lever hoist, is a versatile and portable lifting device commonly used in various industries for lifting and lowering heavy loads. Unlike electric hoists, lever manual hoists are powered by human effort, utilizing a lever mechanism to operate a ratcheting system that pulls a chain or wire rope to lift or lower loads.

Here's an introduction to the key components and functionalities of a lever manual hoist:

Lever Mechanism: The lever mechanism is the primary operating component of a lever manual hoist. It consists of a lever handle that operators manually operate to lift or lower loads. By applying force to the lever, the operator activates the ratcheting system, which pulls the load chain or wire rope through the hoist mechanism.

Ratchet and Pawl System: Inside the lever mechanism, a ratchet and pawl system is employed to convert the linear motion of the lever into rotational motion. As the lever is pulled, the ratchet engages with the pawl, allowing the chain or wire rope to be pulled through the hoist mechanism in one direction while preventing it from slipping backward.

Load Chain or Wire Rope: Lever manual hoists utilize either a load chain or wire rope to lift and lower loads. The load chain is typically made of high-strength steel and is designed to withstand heavy loads. Wire rope versions use a durable steel cable with similar lifting capabilities.

Lifting Hook: At the end of the load chain or wire rope, there is typically a lifting hook or attachment point. This hook is used to securely connect the hoist to the load being lifted. It may feature a safety latch or locking mechanism to prevent accidental disengagement.

Safety Features: Lever manual hoists are equipped with various safety features to ensure the protection of operators and the integrity of the load being lifted. These may include overload protection mechanisms, which prevent the hoist from lifting loads beyond its rated capacity, as well as safety catches on the lever to prevent accidental operation.

Compact and Portable Design: One of the main advantages of lever manual hoists is their compact and portable design. They are lightweight and easy to transport, making them ideal for use in remote locations or for tasks that require frequent relocation.

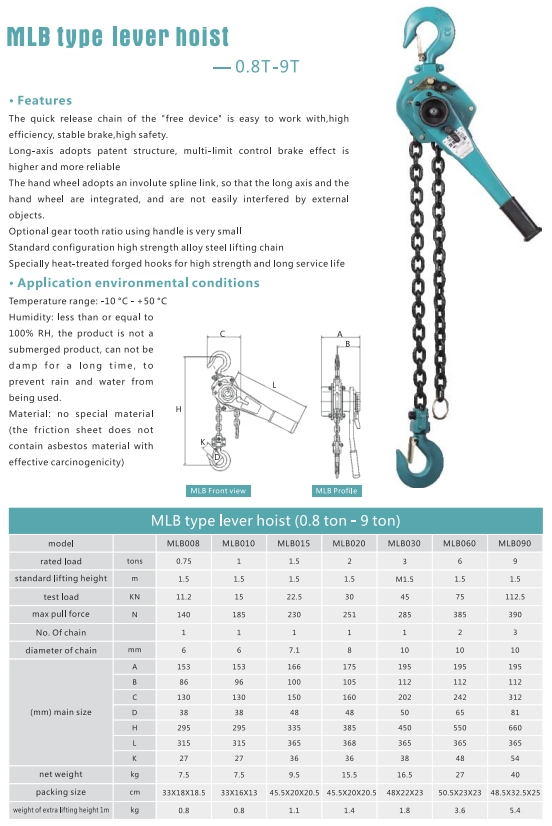

Capacity and Lift Height: Lever manual hoists are available in a range of capacities, typically ranging from a few hundred kilograms to several tons. They also come in various lift heights to accommodate different lifting requirements.

Versatility: Lever manual hoists are versatile tools that can be used for a wide range of lifting and pulling tasks. They are commonly used in construction, maintenance, rigging, and other industrial applications where manual lifting is required.

In summary, lever manual hoists provide a cost-effective and efficient solution for lifting and lowering heavy loads in various industrial settings. Their simple yet robust design, combined with their ease of use and portability, makes them indispensable tools for professionals who require reliable lifting capabilities in their day-to-day operations.

X