中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

A hand chain hoist is a mechanical device used for lifting heavy loads by manual operation. It's a versatile tool commonly found in various industries, construction sites, warehouses, and workshops. Hand chain hoists are designed to provide a reliable and cost-effective solution for lifting applications where electricity or other power sources may not be available or practical.

Here's an introduction to the components and operation of a typical hand chain hoist:

Load Chain: The load chain is the primary component responsible for lifting the load. It's made of strong alloy steel and consists of interconnected links. The load chain is designed to withstand heavy loads and provide durability.

Hand Chain: The hand chain is used by the operator to manually lift and lower the load. It's connected to the load chain and is typically operated by pulling on one end of the chain to lift the load and releasing it to lower the load.

Lifting Mechanism: Inside the hoist, there's a lifting mechanism that translates the pulling motion of the hand chain into lifting or lowering of the load. This mechanism typically consists of gears, pawls, and sprockets that engage with the load chain to lift the load securely.

Hooks: Hand chain hoists are equipped with hooks on both ends for attaching to the load and the lifting point. These hooks are usually forged steel and may have safety latches to prevent accidental detachment from the load.

Load Brake: A load brake is a safety feature integrated into the hoist mechanism to prevent the load from falling in case of a sudden release of tension on the hand chain. It engages automatically to hold the load securely in position.

Housing/Casing: The housing or casing of the hand chain hoist encloses and protects the internal components, providing durability and safety. It's usually made of robust materials such as cast iron or aluminum alloy.

Operation of a hand chain hoist typically involves the following steps:

Attach the Hoist: Securely attach the hoist to a stable anchor point or an overhead beam using appropriate rigging hardware.

Attach the Load: Use the hooks provided on the hoist to securely attach the load to be lifted. Ensure that the load is balanced and properly centered under the hoist.

Operate the Hand Chain: Begin lifting the load by pulling on the hand chain in a smooth and controlled manner. Continue pulling until the load reaches the desired height.

Lower the Load: To lower the load, slowly release tension on the hand chain while maintaining control over the descent speed. The load brake will engage automatically to hold the load securely in place.

Disconnect the Load: Once the load is safely lowered to the ground or its destination, detach it from the hoist hooks.

Store the Hoist: When not in use, store the hand chain hoist in a dry and secure location, preferably away from harsh environmental conditions.

Hand chain hoists come in various capacities to accommodate different load requirements, ranging from light-duty to heavy-duty applications. Proper training and adherence to safety guidelines are essential when operating hand chain hoists to prevent accidents and ensure efficient lifting operations.

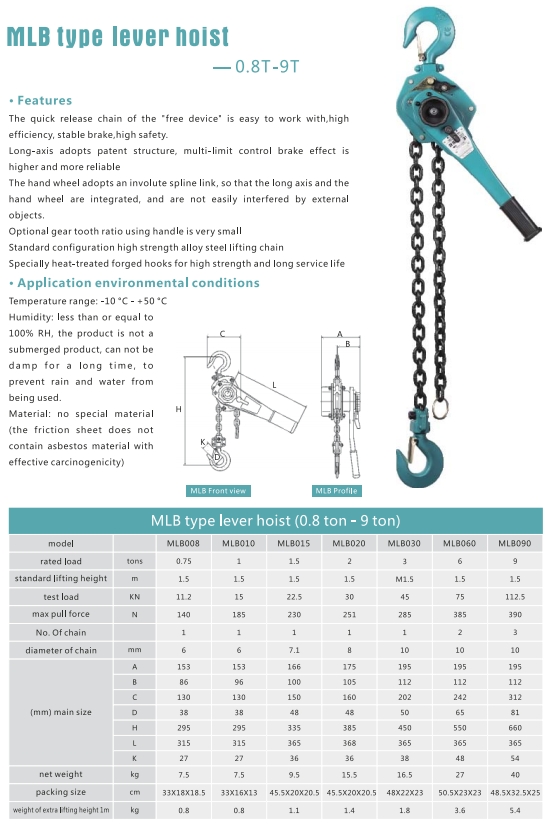

The main equipment produced by Hebei Makita: stage electric hoist, electric chian hoist, wire rope electric hoist,manual hoist, lever hoist, pneumatic hoist and other lifting equipment

X