中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

A prototype lever hoist is an early version or sample of a lever hoist that is developed to test and evaluate its design, functionality, and performance before mass production. Prototypes play a crucial role in the product development process, allowing engineers and designers to refine and optimize the hoist design based on feedback and testing results. Here's a detailed introduction to the components, features, and development process of a prototype lever hoist:

Components:

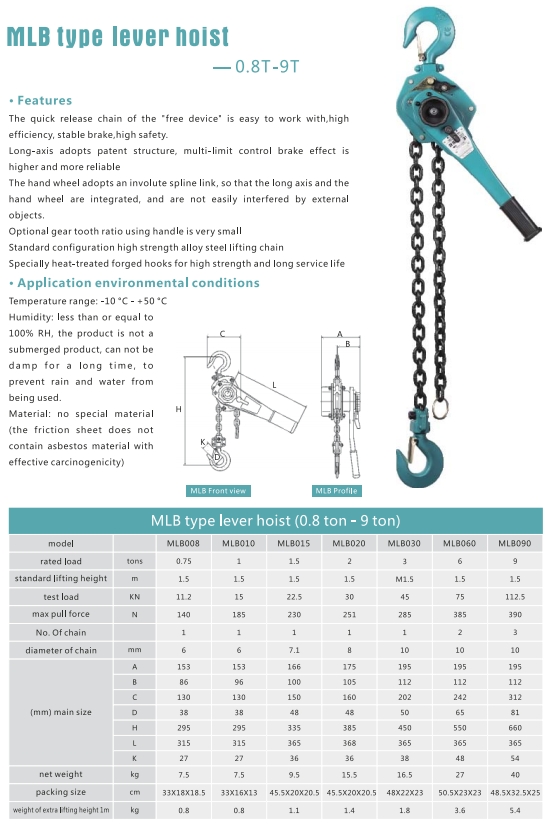

Lever Mechanism: The lever mechanism is the core component of the lever hoist prototype. It typically consists of a lever handle, gears, pawls, and a ratchet system. The lever mechanism converts manual input force into lifting or pulling motion.

Load Chain: The load chain is an essential part of the lever hoist, responsible for lifting or pulling heavy loads. It is made of high-strength alloy steel and consists of interconnected links.

Hooks: The lever hoist prototype is equipped with hooks on both ends for attaching to the load and the lifting point. These hooks are usually forged steel and may have safety latches to prevent accidental detachment from the load.

Housing/Casing: The housing or casing of the lever hoist prototype encloses and protects the internal components, providing durability and safety. It is typically made of robust materials such as cast iron or aluminum alloy.

Features:

Mechanical Advantage: The lever mechanism provides a mechanical advantage, allowing the operator to lift or pull heavy loads with relatively less effort.

Safety Features: Prototype lever hoists often incorporate safety features such as overload protection devices, load brakes, and safety latches on the lifting hooks to prevent accidents and ensure safe lifting operations.

Ease of Operation: The prototype lever hoist is designed for ease of operation, with ergonomic lever handles and smooth pumping action for efficient lifting or pulling.

Durability: Prototype lever hoists are constructed from high-quality materials to ensure durability and reliability, even in demanding industrial environments.

Development Process:

Conceptualization: The development process begins with conceptualizing the design and functionality of the lever hoist prototype. Engineers and designers brainstorm ideas and create initial sketches or CAD (Computer-Aided Design) models.

Prototyping: Once the initial design concept is finalized, a prototype lever hoist is manufactured using rapid prototyping techniques or traditional machining methods. The prototype is assembled, and all components are tested for fit and functionality.

Testing and Evaluation: The prototype lever hoist undergoes rigorous testing and evaluation to assess its performance under various operating conditions. Testing may include load testing, durability testing, and functional testing to identify any design flaws or areas for improvement.

Refinement: Based on testing results and feedback, the design of the lever hoist prototype is refined and optimized. Changes may be made to improve performance, reliability, and user-friendliness.

Iterative Process: The refinement and testing process is iterative, with multiple prototype iterations being developed and tested until the design meets the desired performance criteria and quality standards.

Finalization: Once the prototype lever hoist meets all requirements and passes testing, the final design is ready for mass production. Detailed engineering drawings and specifications are prepared for manufacturing, and production tooling is developed.

The main equipment produced by Hebei Makita: stage electric hoist, electric chian hoist, wire rope electric hoist,manual hoist, lever hoist, pneumatic hoist and other lifting equipment

X