中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

When using a manual explosion-proof pulley chain hoist in hazardous environments, several risks and potential safety concerns need to be considered to ensure the well-being of personnel and the safe operation of equipment. Here are some of the risks associated with the use of manual explosion-proof pulley chain hoists:

Ignition Sources:

In explosive atmospheres, the generation of sparks or ignition sources is a significant concern. The operation of a manual explosion-proof pulley chain hoist involves moving parts and potential friction, which could produce sparks if the hoist is not designed to prevent them.

Overloading:

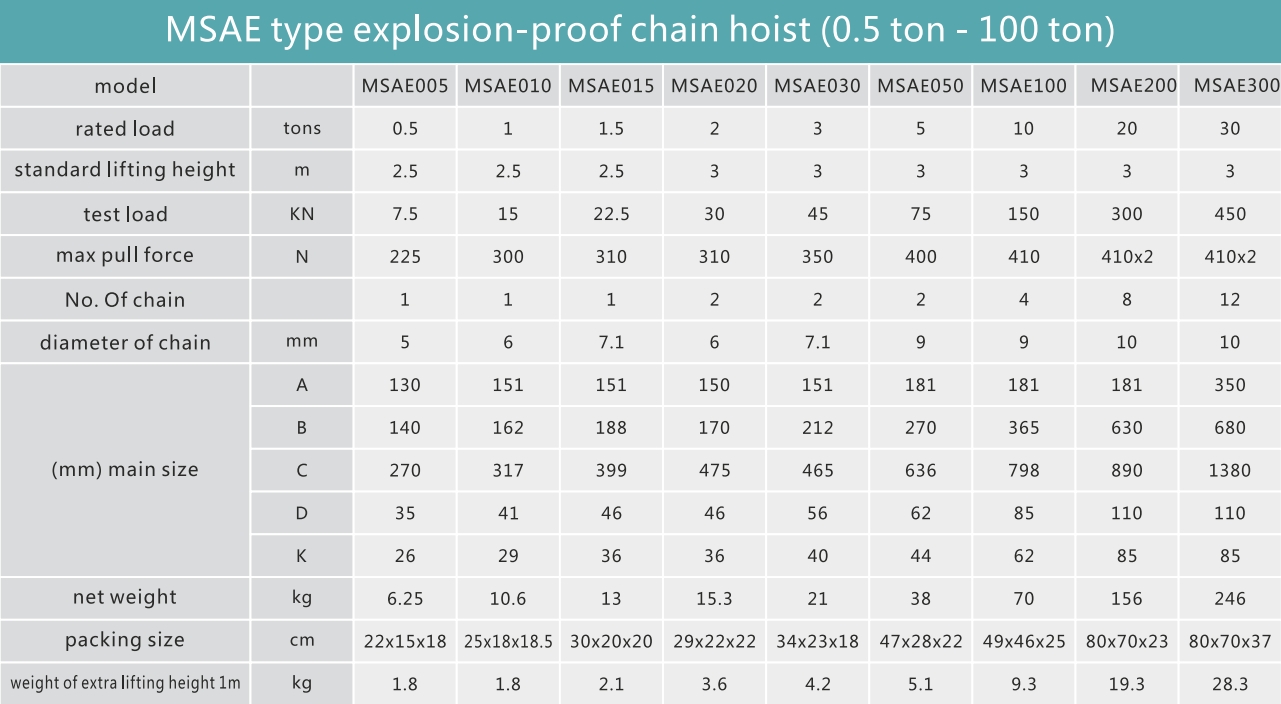

Overloading the hoist beyond its rated capacity poses a risk of equipment failure, leading to accidents and injuries. It is crucial to adhere to the specified load capacity limits and avoid exceeding them during operation.

Misuse and Improper Operation:

Incorrect operation or misuse of the manual explosion-proof hoist can lead to accidents. Users should be properly trained on the correct operation of the hoist, including load handling, braking, and emergency procedures.

Lack of Inspections and Maintenance:

Failure to conduct regular inspections and maintenance can result in worn or damaged components, reducing the hoist's reliability and safety. Inspections should cover load chains, hooks, brakes, and other critical parts.

Environmental Factors:

Environmental conditions, such as temperature extremes, humidity, or exposure to corrosive substances, can impact the performance and safety of the hoist. Ensure that the hoist is suitable for the specific environmental conditions in which it is used.

Improper Grounding:

Inadequate grounding can lead to the buildup of static electricity, increasing the risk of sparks. Proper grounding procedures should be followed as recommended by the manufacturer.

Inadequate Training:

Lack of training or inadequate training of personnel operating the manual explosion-proof hoist can lead to unsafe practices. Proper training is essential to ensure that operators understand the equipment's limitations and safety features.

Non-Compliance with Standards:

Use of a manual explosion-proof hoist that does not comply with relevant safety standards or lacks proper certification increases the risk of accidents. Always verify that the hoist meets applicable safety standards and certifications.

Inadequate Personal Protective Equipment (PPE):

Insufficient or improper use of personal protective equipment, such as flame-resistant clothing or gloves, can expose operators to additional risks in hazardous environments.

Emergency Response Preparedness:

Lack of preparedness for emergency situations, including equipment malfunctions or personnel injuries, can lead to delays in response and exacerbate the severity of accidents.

Inadequate Recordkeeping:

Failure to maintain accurate records of inspections, maintenance, and repairs may result in overlooked issues that compromise the hoist's safety.

To mitigate these risks, it is essential to follow safety guidelines, conduct regular inspections, provide proper training for operators, and ensure that the manual explosion-proof pulley chain hoist is used in accordance with its intended purpose and specifications. Additionally, strict adherence to industry standards and regulations is crucial to maintaining a safe working environment in potentially explosive atmospheres.

X