中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

When using explosion-proof hand chain hoists in hazardous environments, it's crucial to adhere to strict safety guidelines to minimize the risk of accidents and ensure the safety of personnel and equipment. Here are some key considerations and precautions to keep in mind when using explosion-proof hand chain hoists:

Certifications and Compliance:

Ensure that the explosion-proof hand chain hoist is certified and compliant with relevant safety standards and regulations for hazardous locations. Certification labels, such as ATEX or IECEx, should be visible and up-to-date.

Equipment Inspection:

Conduct regular inspections of the hoist before each use to check for any signs of damage, wear, or malfunction. Ensure that all components, including load chains, hooks, and controls, are in good working condition.

Proper Training:

Provide proper training for personnel involved in the operation of explosion-proof hand chain hoists. Training should cover hoist operation, safety procedures, and emergency protocols.

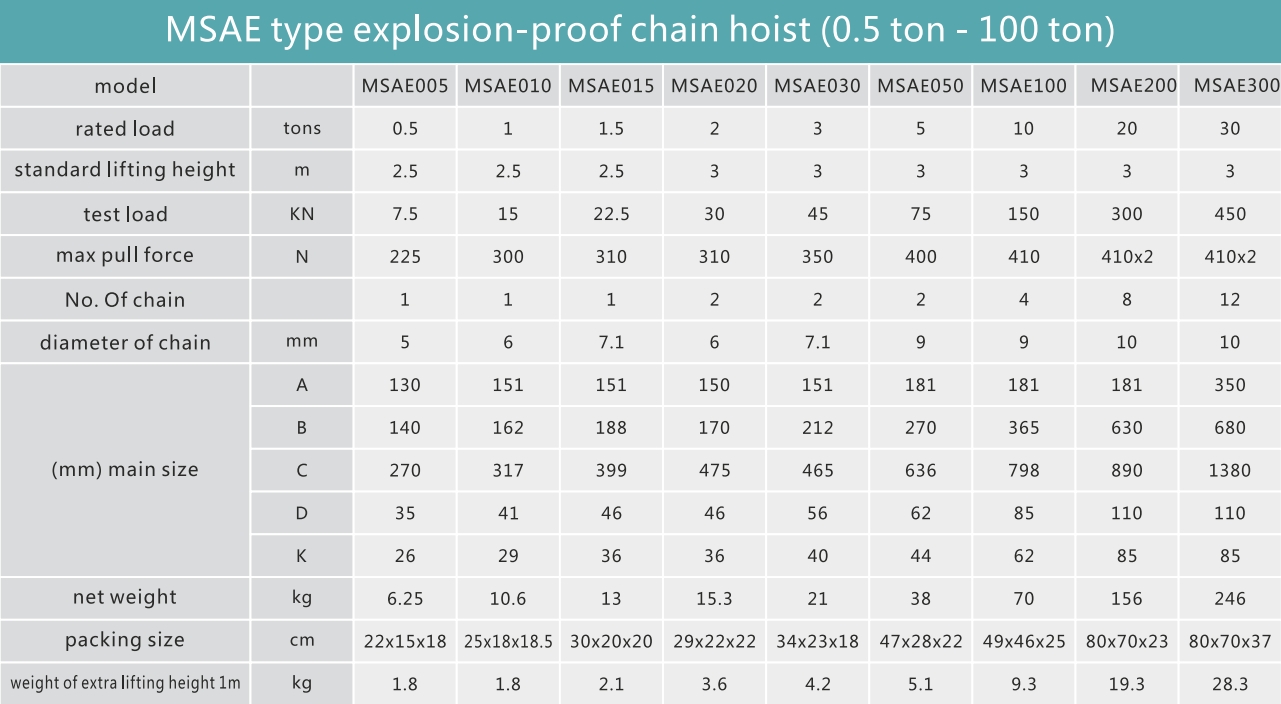

Load Capacity Limits:

Adhere to the specified load capacity limits of the hoist. Overloading the hoist can compromise safety and lead to equipment failure.

Environmental Conditions:

Consider the specific environmental conditions of the hazardous area. Explosion-proof hoists are designed for specific classifications, such as gas groups and temperature classes. Ensure that the hoist is suitable for the given environment.

Use in Designated Hazardous Zones:

Only use explosion-proof hand chain hoists in areas designated as hazardous zones. Avoid using the hoist in non-designated areas, and follow the zoning classifications specified for the equipment.

Avoiding Sparks:

Take precautions to minimize the risk of sparks during operation. This includes avoiding impact, friction, or other actions that could generate sparks. Ensure that the load chain, hooks, and other components are in good condition to reduce the potential for sparking.

Proper Grounding:

Ensure proper grounding of the hoist to prevent the buildup of static electricity. Follow manufacturer guidelines for grounding procedures.

Non-Sparking Tools:

Use non-sparking tools and accessories when working with explosion-proof hoists. This includes tools used for maintenance, adjustments, and any other tasks related to the hoist.

Emergency Procedures:

Establish and communicate clear emergency procedures. Personnel should be familiar with emergency shutdown procedures, evacuation routes, and the proper use of emergency equipment.

Inspection and Maintenance Records:

Keep thorough records of inspections, maintenance activities, and any repairs performed on the hoist. Regularly review and update these records to ensure ongoing safety and compliance.

Exclusion of Non-Explosion-Proof Equipment:

Ensure that only explosion-proof equipment is used in hazardous areas. Exclude non-explosion-proof equipment to prevent the risk of ignition.

Appropriate Personal Protective Equipment (PPE):

Use appropriate PPE, including flame-resistant clothing and other protective gear, as recommended for the specific hazardous environment.

Manufacturer's Recommendations:

Follow the manufacturer's recommendations and guidelines for the proper use, maintenance, and inspection of the explosion-proof hand chain hoist.

Regular Training and Refresher Courses:

Conduct regular training sessions and refresher courses for personnel using explosion-proof hoists to ensure ongoing awareness of safety protocols and best practices.

By following these guidelines and adhering to safety regulations, operators can help create a safer working environment when using explosion-proof hand chain hoists in potentially explosive atmospheres. It's essential to prioritize safety and implement comprehensive safety measures to prevent accidents and protect personnel and assets.

X