中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

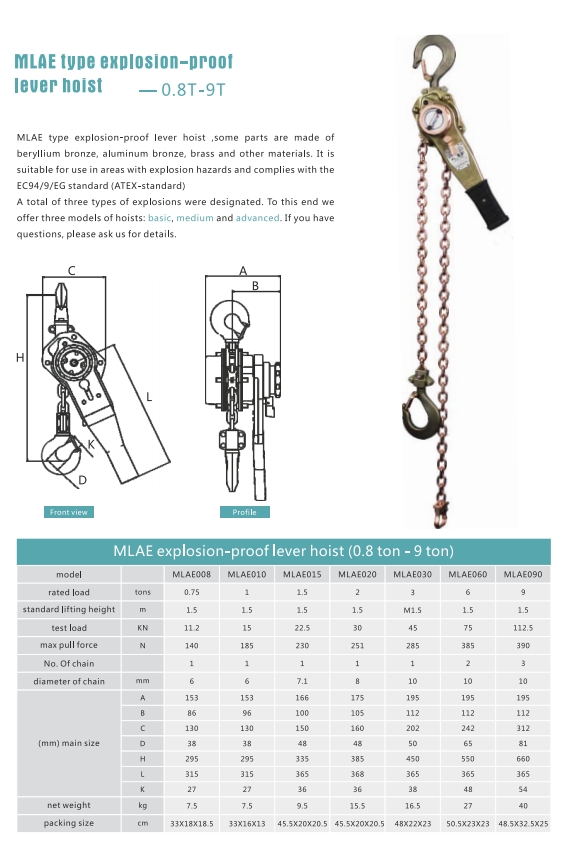

An explosion-proof lever chain hoist is a specialized lifting device designed to operate safely in hazardous environments where there is a risk of explosions due to the presence of flammable gases, vapors, dust, or combustible fibers. These hoists are crucial in industries such as oil and gas, chemical processing, pharmaceuticals, mining, and food processing, where even a small spark can trigger a catastrophic event.

The key features and components of an explosion-proof lever chain hoist typically include:

Explosion-proof construction: These hoists are built with materials and components that prevent sparks, arcs, or other sources of ignition from igniting flammable substances present in the environment. They often have enclosures that contain any potential sparks or heat generated during operation.

Certifications: Explosion-proof hoists must comply with stringent safety standards and regulations set by organizations such as ATEX (Europe), NEC (United States), and IECEx (International). These certifications ensure that the hoists meet the necessary safety requirements for use in hazardous locations.

Lever mechanism: Lever chain hoists utilize a manual lever mechanism to lift and lower loads. This mechanism typically consists of a ratchet and pawl system, allowing for precise control over the lifting process.

Chain: The load is attached to a chain that is wound around a drum or sprocket within the hoist. The chain is made of durable materials capable of withstanding the rigors of lifting heavy loads in challenging environments.

Load capacity: Explosion-proof lever chain hoists come in various load capacities to suit different lifting requirements, ranging from small loads to heavy-duty applications.

Hooks: These hoists are equipped with sturdy hooks for attaching to the load and the lifting point securely. The hooks may feature safety latches or locks to prevent accidental disengagement.

Corrosion resistance: Given the often corrosive nature of the environments where explosion-proof hoists are used, they are typically constructed from materials that resist corrosion, such as stainless steel or aluminum.

Control options: While manual operation is common in lever chain hoists, some models may offer additional control options such as pendant controls or remote control systems for enhanced safety and convenience.

Maintenance: Regular maintenance and inspection are essential to ensure the continued safe operation of explosion-proof lever chain hoists. This includes checking for wear and tear, lubricating moving parts, and verifying that all safety features are functioning correctly.

In summary, explosion-proof lever chain hoists are specialized lifting devices designed to operate safely in hazardous environments where the risk of explosion is present. They incorporate specific features and certifications to mitigate the risk of ignition and ensure the safety of personnel and equipment in these challenging conditions.

X