中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

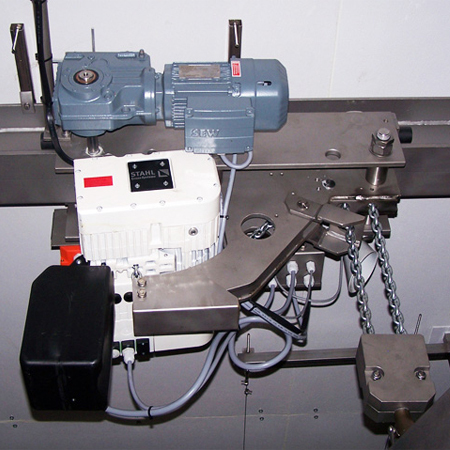

MAKITA aluminum beam combined crane belongs to the combined beam crane, KBK flexible rail crane is characterized in girder material, aluminum girder crane girder combined with high strength Aluminum Alloy a extrusion, greatly reducing the weight of the crane moving part, operating force is only 55% of the steel girder, is a more humanized material handling solutions; in addition, the machining accuracy of aluminum beam is higher, the rail surface more smooth, less resistance.

MAKITA aluminum main beam adopts a special track section design, compared to other products on the market, this design can achieve greater span application.

At present, the domestic MAKITA aluminum beam composite crane, lifting weight between 75kg-1000kg, the total length of the main beam up to 10m.

MAKITA aluminum girder crane combination can complete the most difficult task of overhead crane, can bear frequent overhead material delivery; can choose suspension mounted or free-standing installation, use standard prefabricated modular design structure, can be easily extended with the work unit and the expansion of heart.

The aluminum main beam adopts the same closed track design as the steel main beam, and the safety factor is not less than 5 times. Allowed to scratch the L/450, higher than the national standard of L/250. The design standard is ANSI B30.11. )

It adopts high strength aluminum alloy material once extrusion forming, unique track section design;

Compared with the same steel track equipment, the weight is lighter, and the weight reduction can be as high as 45%;

Modular design allows the use of steel fixed rails to reduce costs;

It is easy to install and expand, and the station layout is more flexible;

X