中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

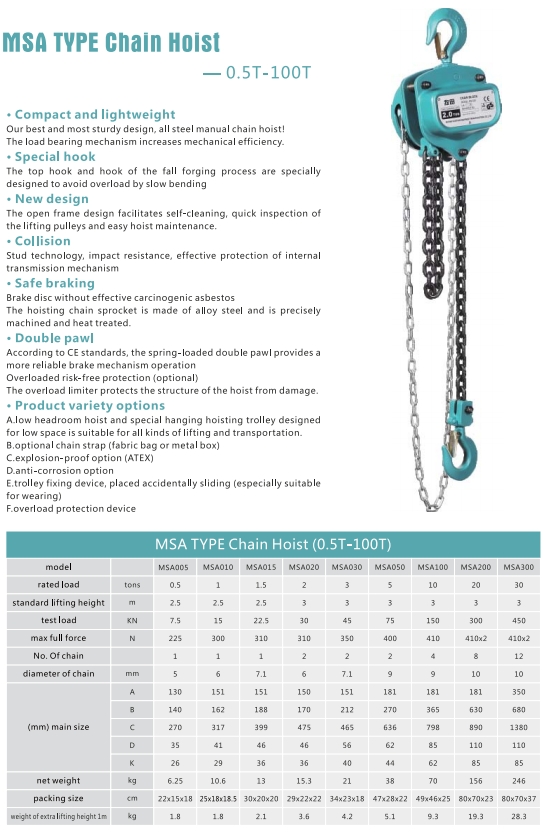

A chain hoist is a mechanical device used for lifting, lowering, and moving heavy loads in a controlled manner. It is a type of lifting equipment that operates manually, electrically, or pneumatically, and it typically consists of a chain, a lifting hook or other attachment, and a mechanism to raise or lower the load. Chain hoists are widely used in various industries for tasks such as construction, manufacturing, maintenance, and material handling.

Here's a brief introduction to the key components and types of chain hoists:

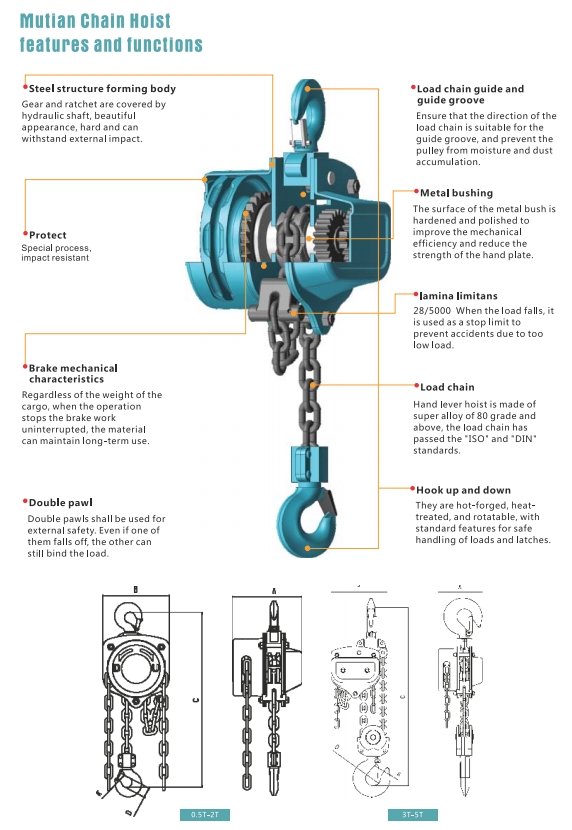

Components:

Chain: The lifting medium of a chain hoist is a chain made of alloy steel. The chain is designed to handle heavy loads and is often heat-treated for strength.

Hook: The lifting hook is attached to the chain and is used to secure and lift the load. It may have a latch or safety catch to prevent accidental release.

Housing: The housing, or shell, encases the internal mechanisms of the hoist, providing protection and support. Housings are commonly made of aluminum or steel.

Mechanism: The mechanism within the hoist can be operated manually, electrically, or pneumatically. Manual chain hoists are hand-operated, electric chain hoists use an electric motor, and pneumatic chain hoists are powered by compressed air.

Types of Chain Hoists:

Manual Chain Hoists: Operated by hand, manual chain hoists are suitable for lighter loads and applications where precise control is required. Users pull a hand chain to lift the load.

Electric Chain Hoists: These hoists are powered by electric motors, providing greater lifting capacity and efficiency. They are often used in industrial settings where frequent or heavy lifting is required.

Pneumatic Chain Hoists: Also known as air chain hoists, these hoists use compressed air to lift and lower loads. They are suitable for environments where electricity is not preferred or poses a safety risk.

Applications:

Construction: Chain hoists are commonly used in construction for lifting and positioning heavy materials and equipment.

Manufacturing: In manufacturing settings, chain hoists aid in assembly processes, material handling, and moving heavy machinery.

Maintenance and Repair: Chain hoists are valuable tools for maintenance tasks, such as lifting and replacing equipment or components.

Warehousing: They are used in warehouses for loading and unloading heavy goods from trucks and containers.

Safety Considerations:

Users should be trained in the proper operation of chain hoists to ensure safety.

Regular inspection and maintenance are essential to identify any issues and prevent accidents.

Follow manufacturer guidelines and industry safety standards during use.

Chain hoists play a crucial role in facilitating the movement of heavy loads in a wide range of industries, contributing to increased efficiency and safety in various lifting applications.

X