中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

A hand chain hoist is a manual lifting device designed to raise, lower, and position loads by utilizing the physical effort of an operator. It is a versatile and widely used tool in various industrial, construction, and maintenance settings where a portable and manually operated lifting solution is required. Hand chain hoists are valued for their simplicity, durability, and the ability to handle a range of load capacities.

Components of a Hand Chain Hoist:

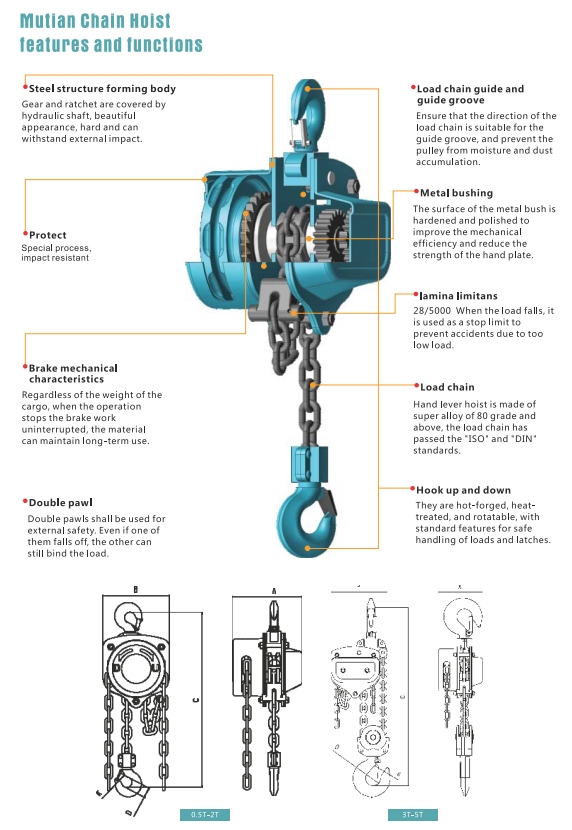

Load Chain:

The load chain is a strong and durable chain that is looped around the lifting gears and pulleys. It supports the load and is usually made of alloy steel for strength and resilience.

Hand Chain:

The hand chain is the manual control mechanism that an operator uses to lift or lower the load. It is connected to the load chain and typically features a comfortable grip for ease of use.

Load Hook:

The load hook is attached to the load chain and serves as the point of attachment for the load being lifted. It often features a safety latch to secure the load.

Bottom Block:

The bottom block contains the pulleys or sheaves over which the load chain travels. It houses components such as the load hook and swivels to allow free movement during lifting.

Gears and Gear Train:

Gears provide mechanical advantage, allowing the operator to lift heavier loads with less physical effort. The gear train transmits the force applied by the hand chain to the load chain.

Pawl and Ratchet System:

The pawl and ratchet system is a safety feature that engages to prevent the load from descending when the hand chain is released. It ensures controlled lifting and lowering of the load.

Brake Mechanism:

Some hand chain hoists incorporate a braking system to control the descent of the load and prevent free-fall, adding an extra layer of safety.

Enclosure and Housing:

The internal components of the hand chain hoist are enclosed within a robust housing to protect them from external elements and ensure smooth operation.

Working Principle:

Lifting:

The operator pulls the hand chain in a downward motion. This action engages the gears and lifts the load via the load chain.

Lowering:

To lower the load, the operator pulls the hand chain in an upward motion. The pawl and ratchet system disengages, allowing for controlled descent.

Applications of Hand Chain Hoists:

Construction Sites:

Lifting construction materials and equipment.

Positioning heavy components during construction.

Warehouses:

Loading and unloading goods.

Moving heavy items within the warehouse.

Maintenance and Repair:

Lifting and positioning equipment for maintenance tasks.

Manufacturing:

Handling machinery and components during production.

Utilities and Power Plants:

Lifting heavy equipment during maintenance operations.

Emergency Situations:

Search and rescue operations.

Lifting and moving debris in disaster response.

Hand chain hoists are prized for their reliability, portability, and the fact that they don't require external power sources. They are essential tools for tasks where manual control is preferred or where access to electricity is limited. Regular maintenance and adherence to safety guidelines are crucial for the safe and effective use of hand chain hoists.

X