中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

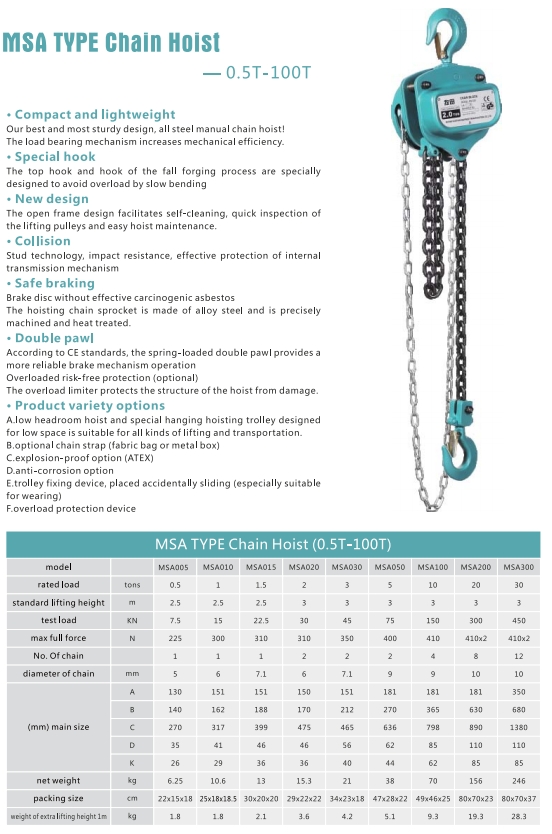

A hand chain hoist crane, often simply referred to as a hand chain crane, is a type of lifting equipment that combines a manual chain hoist with a crane configuration. This portable and versatile device is widely used for lifting, lowering, and positioning heavy loads in various industrial and construction applications. Hand chain hoist cranes are particularly useful in locations where a permanent overhead crane system is not feasible or practical.

Here's an introduction to the key components and features of a hand chain hoist crane:

Components:

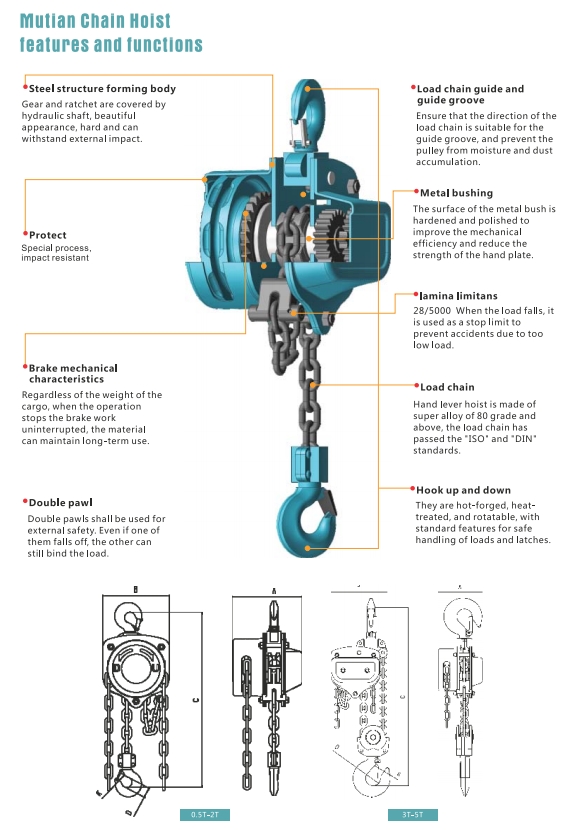

Hoist Unit: The hoist unit is the central component that includes the manual chain hoist mechanism. It consists of a hand chain for manual lifting and lowering, a load hook or other lifting attachment, and gears that facilitate the lifting process.

Crane Structure: The crane structure typically comprises a horizontal beam (bridge) and vertical supports (legs or posts). The crane can be designed to be freestanding or mounted to existing structures, such as walls or columns.

Trolley: Some hand chain hoist cranes are equipped with a trolley, which allows horizontal movement along the bridge beam. The trolley enables the operator to position the load precisely.

Types of Hand Chain Hoist Cranes:

Freestanding Crane: This type of crane is self-supporting and does not require additional support structures. It is portable and can be moved to different locations within a facility.

Wall-Mounted Crane: Mounted to a vertical surface, such as a wall or column, this type of crane is suitable for applications where floor space is limited.

Ceiling-Mounted Crane: Suspended from the ceiling, this crane type maximizes floor space and is commonly used in facilities with high ceilings.

Applications:

Workshops and Factories: Hand chain hoist cranes are often used in manufacturing and workshop environments for lifting and positioning heavy machinery, tools, or materials.

Construction Sites: Portable hand chain hoist cranes are valuable on construction sites for tasks such as lifting building materials, equipment, or tools to elevated areas.

Warehouses: Hand chain hoist cranes are employed in warehouses for loading and unloading goods from shelves or pallets.

Maintenance and Repair: These cranes are useful for maintenance tasks, allowing easy and controlled handling of heavy components.

Advantages:

Portability: Hand chain hoist cranes are often designed to be portable, allowing them to be moved to different locations as needed.

Cost-Effective: They offer a cost-effective solution for lifting applications without the need for a permanent overhead crane system.

Versatility: The combination of a manual chain hoist and crane configuration provides versatility for various lifting tasks.

Safety Considerations:

Load Capacity: Adhere to the crane's specified load capacity, and never exceed its rated limit.

Operator Training: Ensure that operators are trained in the safe use of hand chain hoist cranes.

Regular Inspections: Conduct regular inspections to identify and address any wear, damage, or issues with the crane components.

Hand chain hoist cranes are valuable tools in situations where a flexible and portable lifting solution is required. However, it's crucial to prioritize safety and adhere to proper operating procedures to prevent accidents and ensure efficient lifting operations.

X